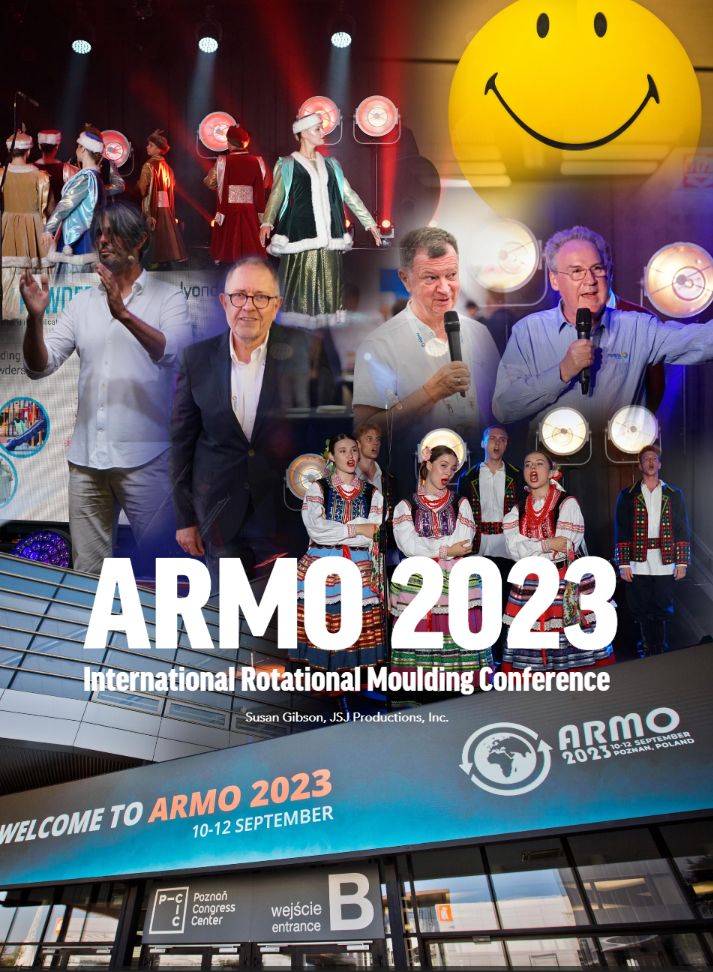

ARMO 2023 - building a sustainable future for the rotomoulding industry

Last year’s ARMO conference was a remarkable event for the rotomoulding industry. The conference attracted 570 participants from all over the world. Among them were companies committed to sustainable efforts in plastics production, ready to discuss recycling, post-consumer materials and sustainability in rotational moulding technology. As Rotovia, we were pleased to participate in the conference, also as one of the sponsors of the event.

Sustainability - our commitment to transforming the industry

One of our top priorities is building a sustainable future for the plastics industry. We know that the challenges facing the industry are enormous. That is why we are focusing on measures to protect our environment. We are developing several initiatives where we aim to reduce our carbon footprint, reduce fossil fuel energy consumption and minimise the amount of waste generated by our operations.

In a speech entitled ‘Rotovia – our road to sustainability’, given during the conference, Rotovia CEO Dadi Valdimarsson presented a sustainable approach in the production of plastic products. In this way, we wanted to highlight the key issues related to the plastics business and also inspire other organisations to adopt green practices and sustainable operations in the rotomoulding sector.

Innovative approach - from recycling to process optimisation

At the conference, our stand showcased a unique product, a playground component manufactured using rotational moulding technology with an impressive 33% post-consumer recycled (PCR) content. More information on sustainable rotomoulded playground equipment can be found here.

The use of PCR materials in production just one of our efforts to promote a sustainable approach in the industry. Details of our sustainability strategy can be found in our Sustainable Report, which we published in February 2024. This report presents our sustainability activities, as well as the milestones we have achieved in 2023.

Our growth strategy to 2028 focuses on the efficient use of resources and the optimisation of production processes. We aim to reuse more than 20% of the materials in our new products to reduce our environmental impact and promote a circular economy. Product reuse is a key element in reducing the environmental impact of a product throughout its life cycle. This practice not only saves valuable resources, but also significantly reduces the amount of waste generated both during the manufacturing process and the waste generated by products with a short lifespan. At Rotovia, we place great importance on designing products with recycling in mind.

ARMO 2023 Conference - a strong impulse for sustainable rotomoulding

Last year’s ARMO 2023 Conference was not only an opportunity for us to showcase our achievements but also to share experiences and inspiration with other industry leaders. Initiatives such as the ARMO Conference play an important role in spreading awareness of sustainable practices in our industry and mobilising environmental action. We believe that together we can develop innovative solutions that will contribute to building sustainable future for rotomoulding, making our industry more responsible and environmentally friendly.

Below is an article from Rotoworld magazine, issue 4, from 2023 on the September ARMO conference in Poznań (Poland).

We encourage you to read it!