Rotomoulded plastic boat components

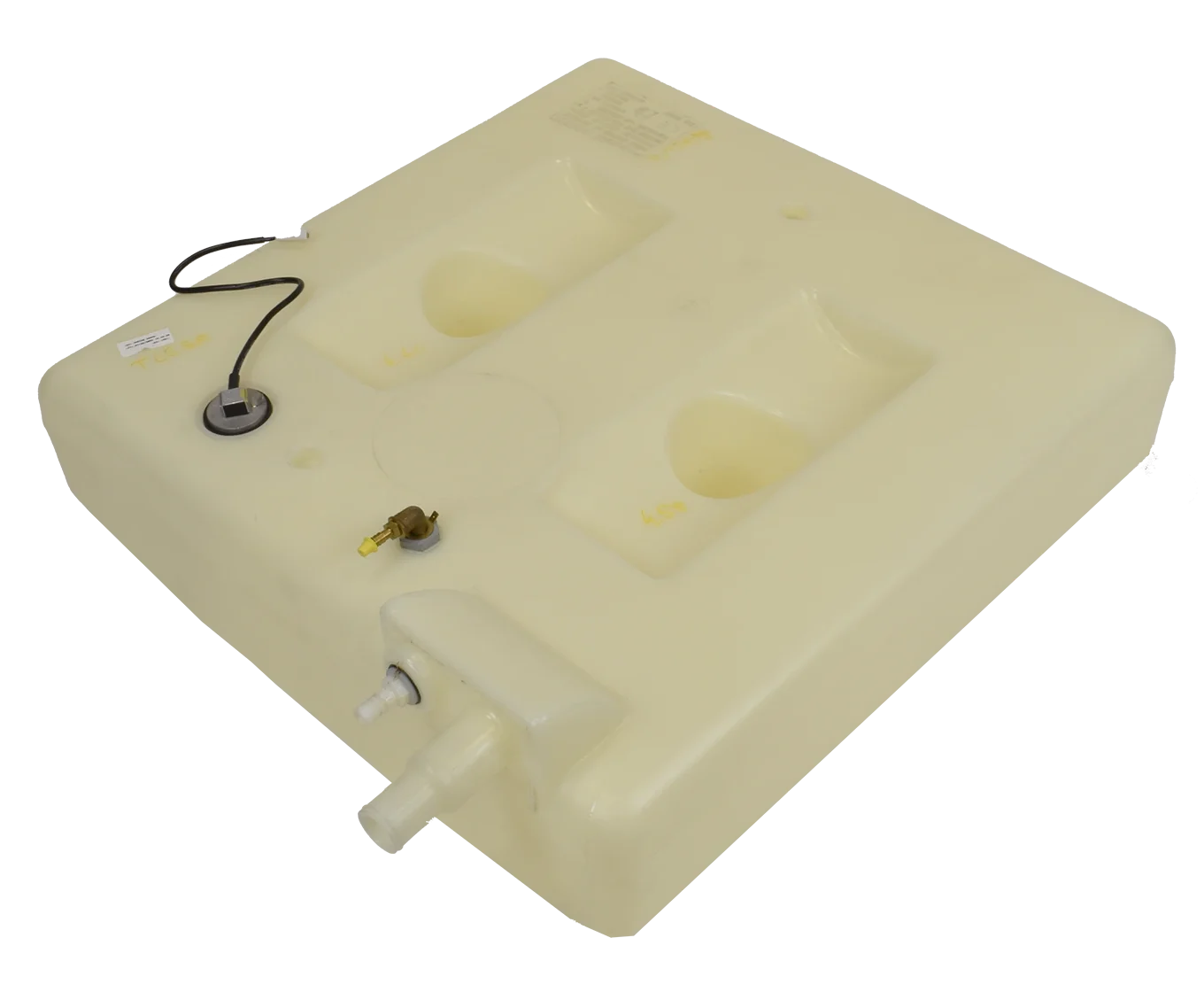

Rotovia has been active in making rotomoulded plastic components for leisure vehicles such as boats, caravans, and campers for many years. Every boat is a combination where many different parts such as gasoline tanks, fuel tanks, water tanks, water locks, and holding tanks come together resulting in a fantastic vessel that meets the highest standards of the demanding expectations of the buyers. Lots of those parts in yachts or boats are made of plastic because this saves a lot of weight compared to other materials. Rotovia uses the rotomoulding process to produce the product of your idea. As the manufacturer of those vessels chosen for plastic components that are being produced rotomoulding has many benefits. For example; a wide range of shapes and sizes and can be tailored to the specific requirements and available space. But there are more rotomoulded components that can be customized with different colours and features, which helps you as manufacturer to enhance the aesthetic appeal of a boat.

Highly customizable

Functional and aesthetic

Resistant to punctures and scraping

The benefits of water tanks for boats

- Highly customizable

- Functional and aesthetic

- Resistant to punctures and scraping

The unique specifications

- Seamless one-piece construction

- No corrosion

- Lightweight

- Made of 100% PE

- Easily recyclable

The unique benefits

- Compliant with EN ISO 8099-1:2018

- Many different options

- Multi connectable

Freedom in design of boats components

Boat and yacht manufacturers have a wide range of materials to choose from for constructing their boats, including rotomoulding. Rotomoulding offers several benefits over traditional methods such as blow molding or injection moulding namely durability, and freedom in design.

But there is more, rotomoulded plastic parts are extremely resistant to impact, UV radiation, and other environmental factors that can cause damage over time. This makes them ideal for use in the marine environment, where exposure to sun, saltwater, and other tropical; conditions is common. Rotomoulded boat components are also resistant to corrosion, which is a major concern for boat and yacht manufacturers, as it can lead to costly repairs and maintenance.

Łukasz

Sales manager

"The harder, the better."

your idea

to life. Start now!