Longlasting rotomoulded plastic parts for mobile compressors

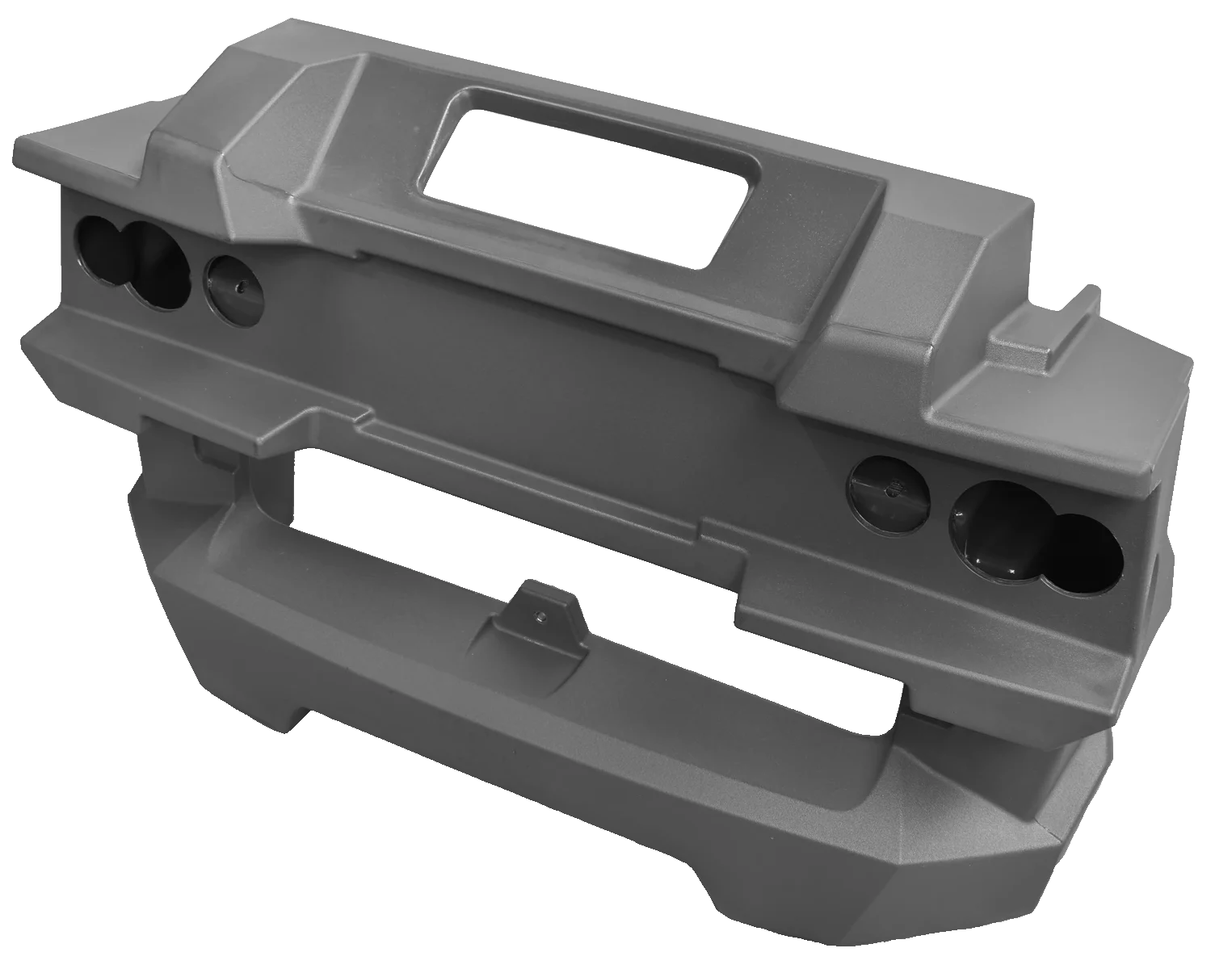

Rotovia is making high quality rotomoulded components for construction and building vehicles for more than 50 years. An unique vehicle within this market segment we make parts for are mobile compressors. The rotomoulded parts that we produce are the best premium solutions for manafacturers who produce compressors that must withstand harsh working conditions. Using rotomoulded plastic products made of HDPE in the manufacturing of mobile compressors, such as bumpers and canopies can bring many benefits for the manufacturers.

To withstand the harsh enviroment of the building and construction sites Rotovia’s components are containing consistent wall thickness and uniform strength, which is important in the production of mobile compressors. The plastic used in rotomoulding is resistant to impact, corrosion, and UV light, which means the components will not deteriorate quickly and will maintain their appearance for a longer period. This also ensures that the mobile compressor will continue to function correctly and efficiently, even in tough environments.

Long-lasting lifetime

High resistant materials

Easy Installation Process

High-resistant rotomoulded compressor components

Using rotomoulded plastic products in mobile compressors brings a huge benefit in weight reduction. Compressor components made of plastic are much lighter than metal or other materials. This reduces the overall weight of the machine, making it more mobile and easier to transport and move around across the different environments. This is particularly important in industries where mobile compressors are used: on construction sites, remote locations, or in off-road conditions.

But there is more, rotomoulded plastic compressor components are versatile and can be manufactured in a wide range of shapes, sizes, and colours. This allows manufacturers to create unique designs that are aesthetically good looking, whilst also ensuring the components are functional and fit perfectly into the machine even with many different inserts applied to the product. The plastic can even be combined with other materials to produce composite products, which provide even more strength and durability. So the time is now, let’s bring your idea to life. Contact us now!

Julia

Sales Manager

"A satisfied customer is the best business strategy of all"

your idea

to life. Start now!