Premium plastic products for wind energy

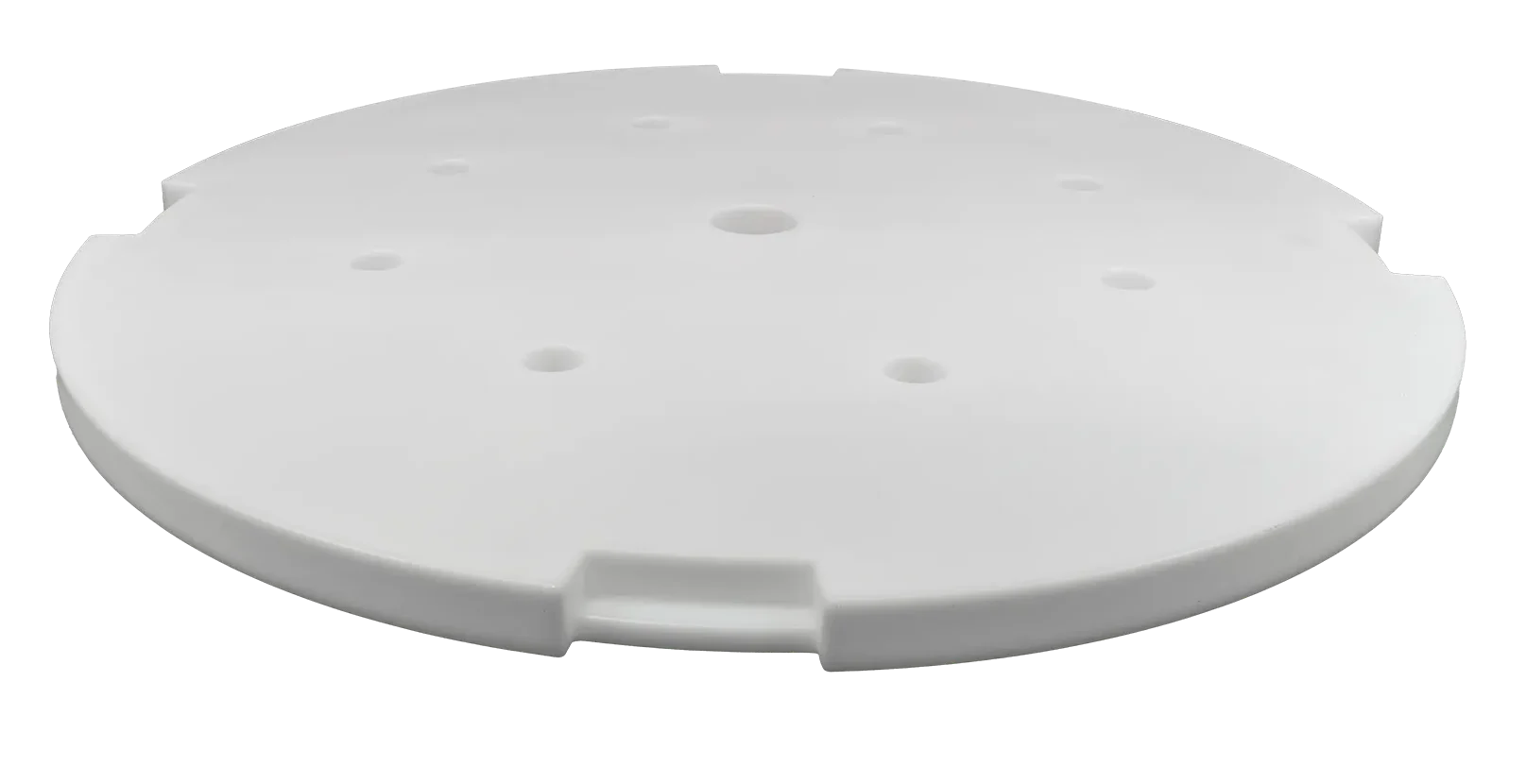

Rotovia has been active in the renewable energy market for many years. A multitude of fantastic and worldwide-operating customers rely on our premium products in wind energy and the upcoming solar energy and hydro energy produced by our Custom Moulding Business. Together with our customers, we aim for sustainable growth in the wind energy industry. Rotovia’s Custom Moulding Business produces high-quality components for the wind energy sector. As an example, we can sustainably rotomould many different parts within the nacelle of windmill houses. You, as the supplier of those nacelles, can trust that your lightweight premium products meet the highest standards in reliability, durability, and performance requirements.

Converting stainless steel products to plastic

Extremely durable under pressure and heat

20+ year life-time without corrosion

Premium specifications of plastic air ducts

The air ducts produced by Rotovia are characterized by unique qualities:

- Optimal airflow

- 20-years lifespan

- Unprecedented design possibilities

The unique specifications

- Optimal use of the available space

- Resistant to fatigue

- Up to 50% weight savings

The unique specifications

- Integration of multiple functions

- Resistant to vibrations

- Large dimensions possible

The unique benefits

- Material resistant to hydraulic oil

- Complex design possibilities

- Up to 50% cheaper than a steel tank

The nacelle of windmill houses

These days the average nacelle cover contains many different components and systems. Adding up every part, system, and component results in a lot of weight. We know from our experience that the typical solutions are stainless-steel products inside the nacelle covers. One of the main benefits of switching to HDPE plastic is the light weight of the material. By switching those stainless-steel products to high-quality plastic products in the nacelle covers, you can save a lot of weight.

Extremely durable windmill parts

The premium products for the wind industry are by made by our rotomoulding process. The unique aspects of our process will make sure that the plastic is evenly spread in the mold. This creates unique one-piece products which are extremely durable under pressure and heat. This is important for manufacturers of modern nacelle covers because this makes sure that during the lifetime of the windmills the premium products produced by Rotovia are durable enough to keep going for years and years. Let’s bring your idea to life! Contact us by filling in the contact form and we start your journey!

Hendrik

Account manager

"My passion is to explore together with the customer the unprecedented possibilities of rotational moulding"

your idea

to life. Start now!