Extremely durable and long-lasting crane parts

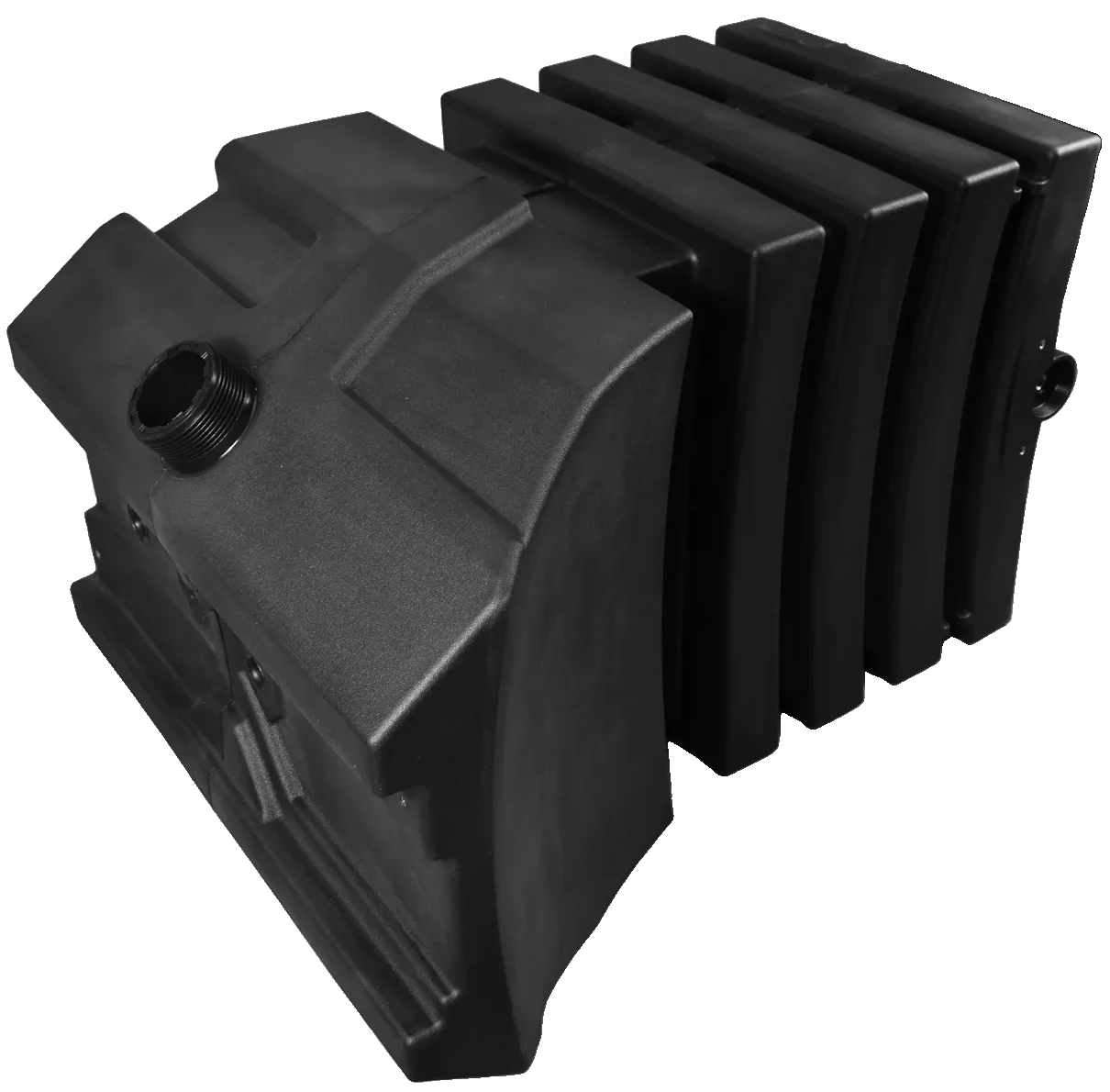

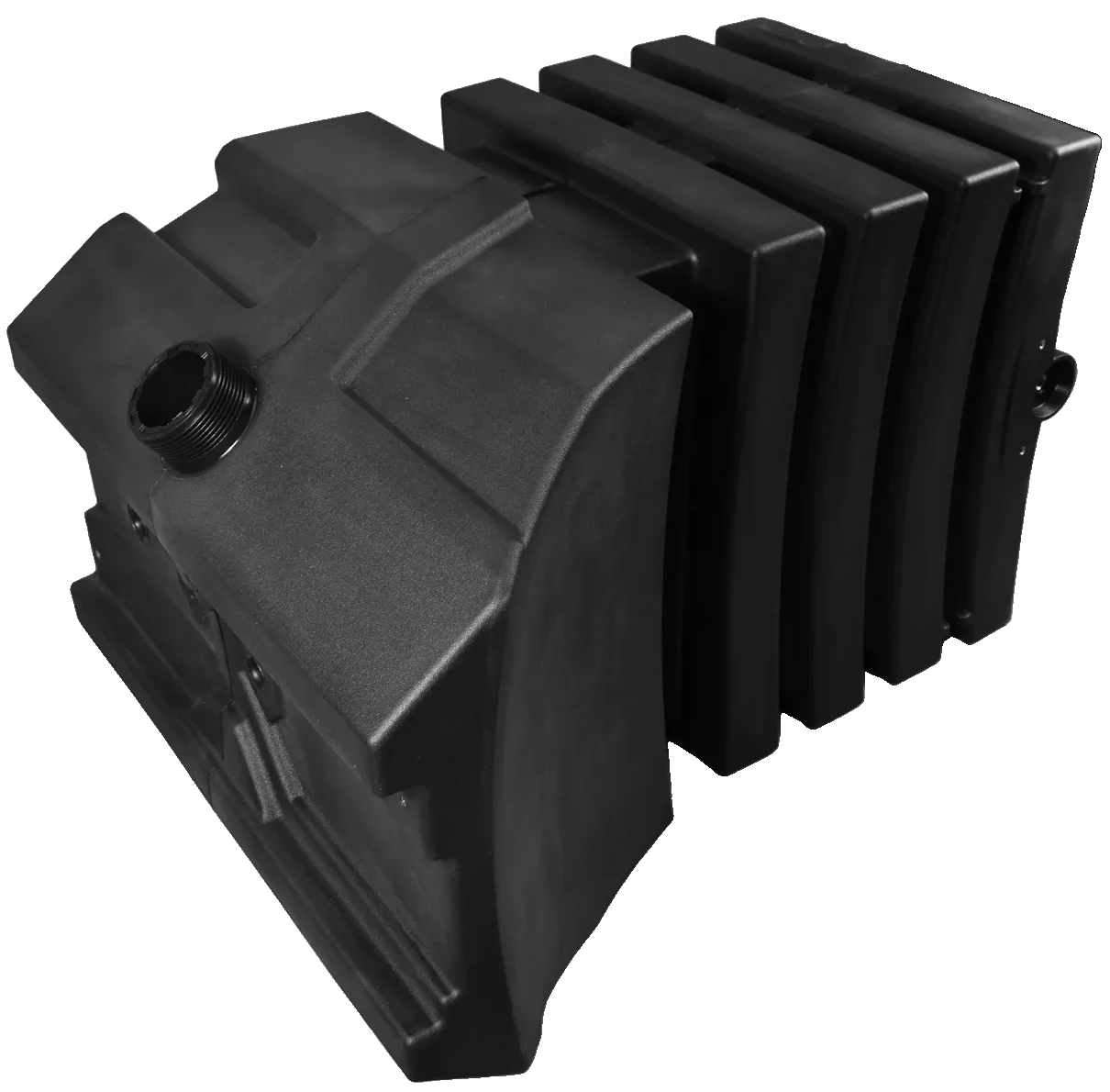

Cranes are one of the biggest segments in building and construction for which the custom moulding business of Rotovia produces premium solutions. For these big industrial machines we produce many different crane parts, such as Adblue tanks, airducts, fuel tanks and hydraulic oil tanks.

Crane manufacturers choose for rotomoulded plastic crane parts because they are extremely durable and long-lasting. They are made from a single piece of plastic, so they do not have any seams or joints that can weaken over time. This means that rotomoulded products, such as fuel tanks and hydraulic oil tanks, will not leak or crack, even under the most demanding conditions.

Long-lasting lifetime

High resistant materials

Easy Installation Process

Light-weight parts for cranes

The products are also resistant to a wide range of chemicals and fuels, making them ideal for use in construction and building machinery. Furthermore, they are resistant to impact and abrasion, which means that they can withstand the rough and tough conditions of construction sites without showing any signs of wear or damage.

Transporting and installing rotomoulded parts for cranes is very easy, because of their light weight. This reduces the overall weight of the machinery, which in turn improves fuel efficiency. The products are also easy to customize to the specific needs of the machinery manufacturer, which means that they can be tailored to fit into the design perfectly.

High-resistance materials for cranes

Manufacturers of cranes benefit from the easy installation process when they use the high-resistant rotomoulded plastic components produced by the custom moulding business of Rotovia. The premium rotomoulded solutions are lightweighed and durable, which ensures a seamless assembly. The simplicity of handling and connecting rotomoulded plastic components streamlines the installation process, allowing crane manufacturers to enhance production efficiency.

But there are more benefits for manufacturers of cranes. There will be a significant advantage by incorporating high-resistant rotomoulded plastic components into their designs. The HDPE or LDPE materials used for the rotomoulded products offers a unique blend of durability, corrosion resistance, and reduced weight, resulting in enhanced crane performance and longevity. High-resistant rotomoulded plastic’s exceptional strength-to-weight ratio contributes to increase the lifetime of the crane part without compromising the quality of the plastic. Its resistance to corrosion ensures prolonged lifespan even in harsh environmental conditions.

Julia

Sales Manager

"A satisfied customer is the best business strategy of all"

your idea

to life. Start now!