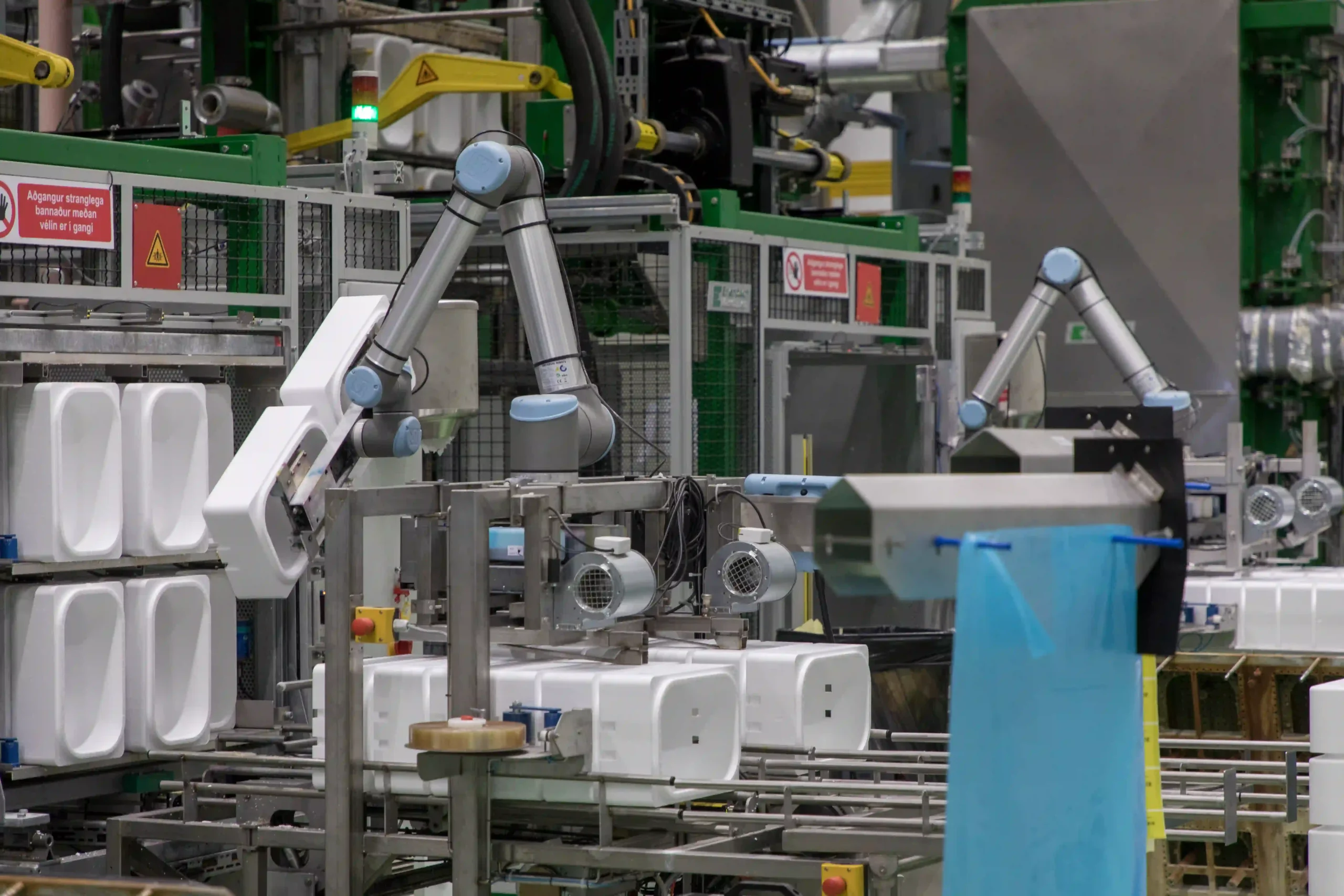

EPS Packaging and Insulation

Our main production is food packaging and housing insulation from EPS but we also offer many of the necessary accessories for the export of perishable goods and fitting of EPS housing insulation.

Because expanded polystyrene (EPS) packaging consists of up to 98% air pores it is normally very light compared to the packaged food. EPS boxes are very well insulated and maintain optimal product temperature longer than e.g. cardboard and corrugated plastic packaging. They are water resistant and the white colour offers protection against thermal radiation and makes it easier to detect possible impurities in food. EPS packaging is strong relative to weight, which is especially important for air transport.

Insulation

EPS in very easy to work with. The material is light and can easily be cut in place or into shape using a common wooden saw or a knife. No dust is formed when the material is used and no special clothing or dust masks neccesary. The material will not change its shape at temperatures between -180°C and +80°C. It is however neccesary to protect the plastic from fire and sources of excess heat with a coating of plaster or some other type of fire and heat resistant material according to building regulation regarding fire and fire hazards.

EPS is commonly placed underneath a plaster coating, be it on the interior or exterior of the wall facing the outside. Such an insulation must have a good moisture resistance as it could easily absorb moisture from the plaster coating and thus increased the migration of humidity within the wall. Should the insulation become frosen, which of course does not happen with an insulation that does not absorb water, it could easily rupture the plaster coating. Furthermore moist insulation can easily reach temperatures of 50-60°C on a sunny day if the coating is of dark colour. It is thus apparent that the affects of sudden temperature changes, which we are so used to in Iceland, can significantly affect the wall system and this needs to keep in mind during the design stages.

Reusability and sustainability

The raw material yield is maximised by high-technology manufacturing equipment. The production of EPS requires only water, environmentally friendly energy, steam and air. No ground water is contaminated during production, usage or recycling of EPS packaging. It is food grade approved and meets all requirements of a modern society. Awareness in recent years on the environmental impact of packaging has led to the consideration of the total environmental cost of each packaging option throughout its life cycle. The amount of natural resources, such as energy, during production and usage of the packaging is important. Furthermore, effects on water usage, pollution and land utilisation must be considered and compared to other options. Plastic is widely used for energy production, thereby decreasing landfill disposal. Plastic is relatively light compared to other food packaging materials, thus requiring lower transport cost. When all this is taken into account, plastic is often the preferred choice for food packaging.

about

Tempra www.tempra.is