Premium rotomoulded truck components

Our position as a trusted provider of premium plastic components is demonstrated through our exceptional rotomoulded truck components. Our expertise enables us to design and craft plastic truck parts that are pivotal for vehicles to operate at peak performance levels, adhering to the highest set industry standards. Our commitment to quality ensures that every plastic truck component enhances the efficiency and longevity of your fleet.

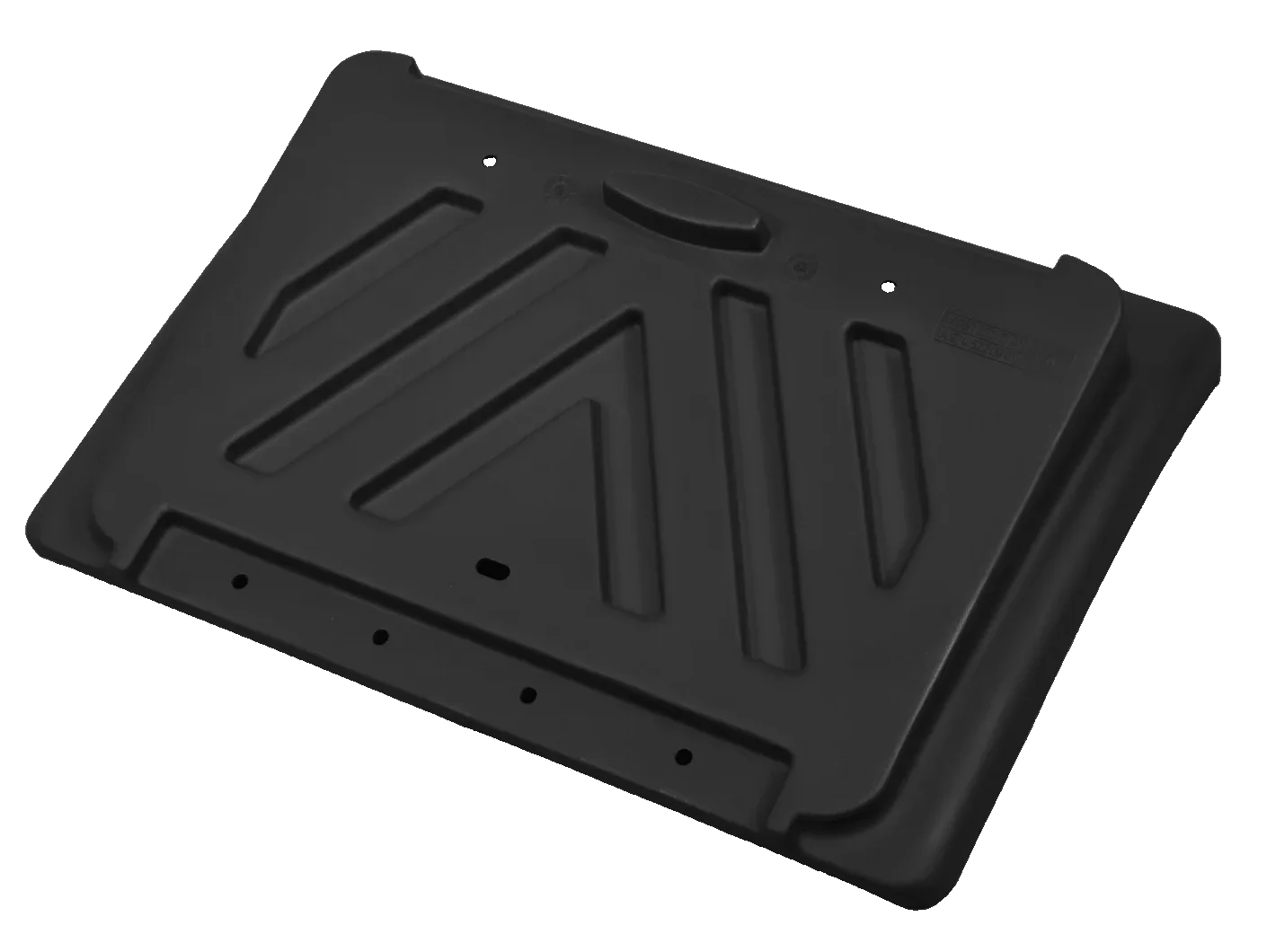

The rotomoulding process we employ fabricates seamless, one-piece plastic truck parts that are remarkably robust and hygienic. This method eliminates joints and seams, preventing bacteria accumulation and simplifying the sanitation process — an essential feature for rotomoulded truck components like fuel tanks, mudguards, battery housings, air inlet ducts, and AdBlue tanks.

Components are precisely designed and manufactured

Complex design to fit limited space

Highly customizable with meeting industry standards

The unique specifications

- Integration of functions

- Individually colored

- Customized surface

Rotomoulded plastic truck components for the roughest conditions

In terms of resilience, our rotomoulded plastic parts set a new benchmark. Engineered to be impact-resistant, immune to corrosion, and able to withstand severe weather conditions, these parts guarantee to endure the strenuous demands trucks face daily. This durability is a significant advantage, protracting the vehicle’s operational life and, as a result, offering a sound investment for truck manufacturers.

Moreover, these plastic truck components contribute to reducing the total weight of the truck, a critical factor in enhancing fuel efficiency and minimizing emissions. The lightweight nature of our premium components does not compromise their strength, making them an exemplary choice for the forward-thinking manufacturer.

Our rotomoulded plastic parts also excel in cost-effectiveness. They offer a budget-friendly solution that leads to substantial savings in the long run by minimizing the necessity for frequent maintenance and part replacement. Ease of installation is another key benefit, as these components are designed for simplicity, requiring no special tools or equipment for assembly.

Julia

Sales Manager

"A satisfied customer is the best business strategy of all"

your idea

to life. Start now!