Lightweight and durable parts for caravans and campers

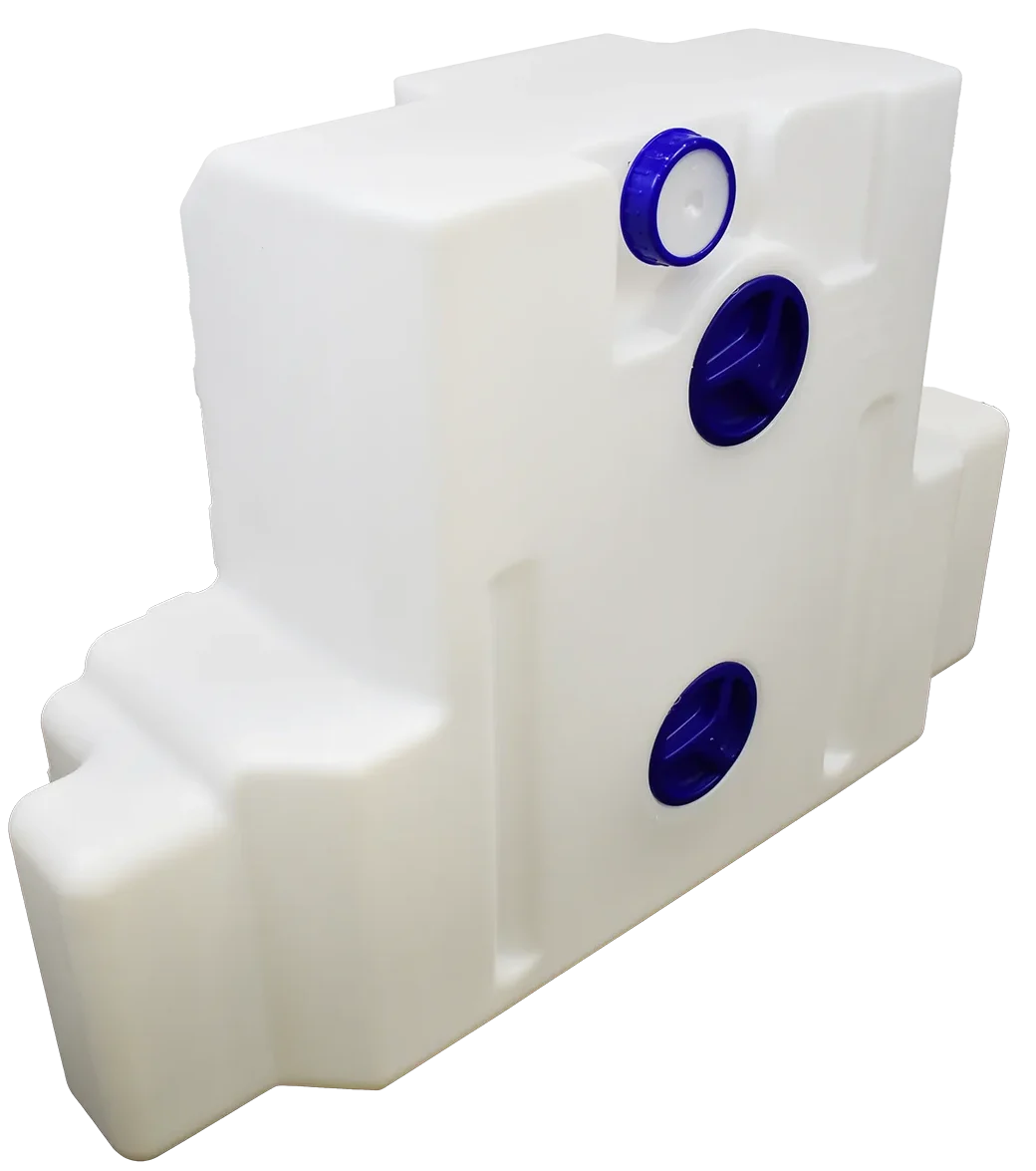

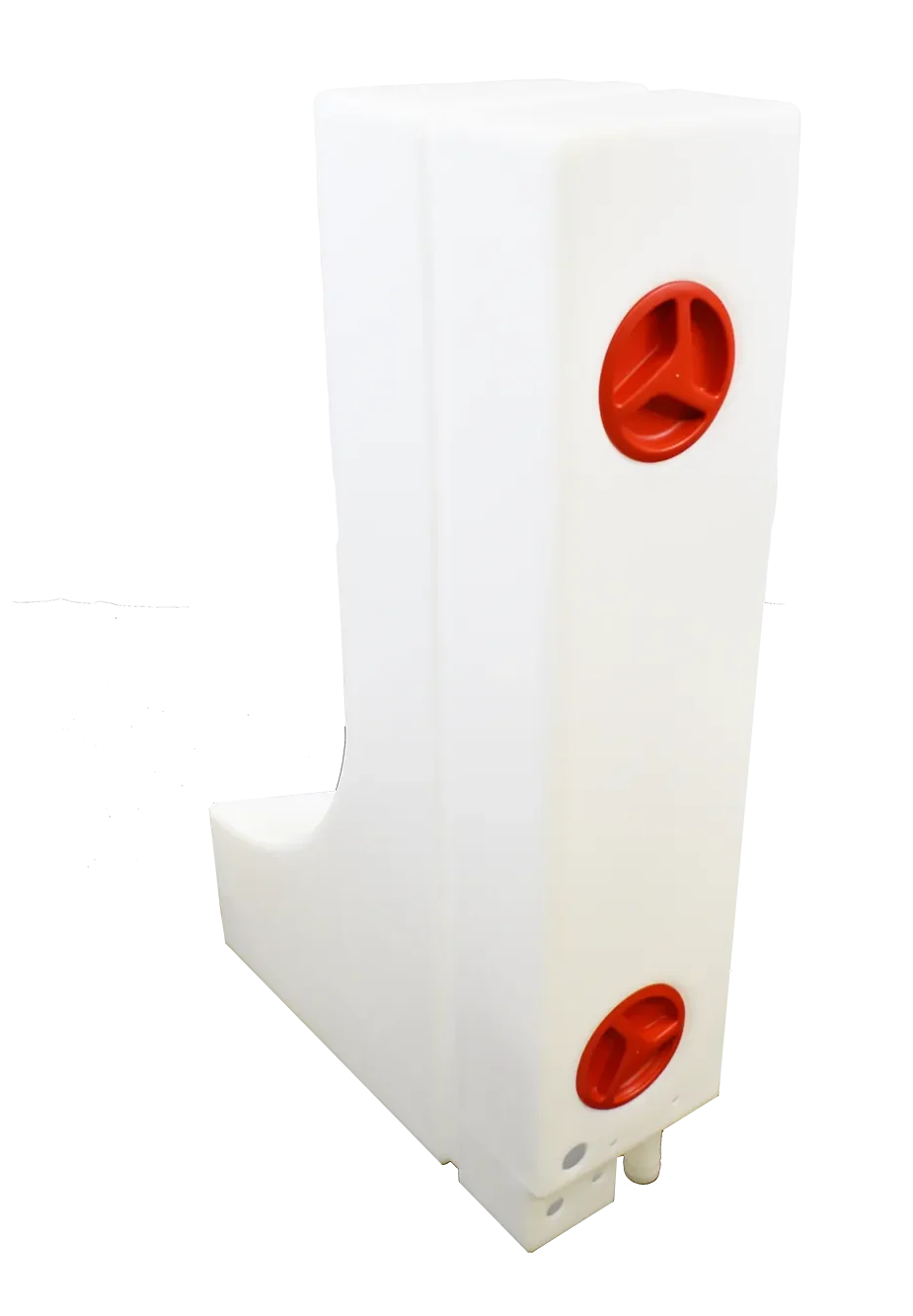

Rotomoulding is often used to create complex-shaped parts such as water tanks, fuel tanks, and waste holding tanks. It is also often used to create parts for leisure such as caravans and campers. There are several benefits to using rotomoulded caravan components.

First, rotomoulding is a cost-effective manufacturing process. The moulds are relatively inexpensive to produce, and the process itself ensures very little material waste. This means that we can create premium quality parts at a lower cost compared to other manufacturing methods.

Second, rotomoulded plastic parts are lightweight and extremely durable. Plastic is a lightweight material, which means that our rotomoulded camper parts can help you reduce the overall weight of your caravan or camper. This can improve fuel efficiency and make the vehicle easier to tow for example. Our camper components are also extremely durable and resistant to impact, which makes them ideal for use in vehicles that are exposed to rough terrain and harsh weather conditions.

Highly customizable

Functional and aesthetic

Resistant to punctures and scraping

Highly customizable caravan and camper components

Rotomoulding allows for the creation of complex shaped parts. This makes it an ideal manufacturing method for creating caravan and camper components like fresh water tanks and grey water tanks which need to be functional, aesthetic and highly customizable. The process is versatile, which means that we can create rotomoulded camper parts in a wide range of colours and finishes. This allows us to add a touch of personality and style to your caravan and campers, which can help to differentiate from competitors.

The process also is environmentally friendly. It uses less energy than other manufacturing methods, and the plastic pellets used can be made from recycled plastic. This means that we can create premium parts while also reducing the environmental impact.

For more information, contact us so we can find the solution you need!

Łukasz

Sales manager

"The harder, the better."

your idea

to life. Start now!