High-quality rotomoulded plastic bus components

In the dynamic world of vehicle manufacturing, especially for buses, trains, and trucks, the emphasis on quality cannot be overstated. At the core of our operations is a firm commitment to providing premium plastic components that not only meet but exceed industry standards. Our positioning as a trusted provider underscores our dedication to delivering components that ensure your vehicles perform optimally, according to the highest set standards.

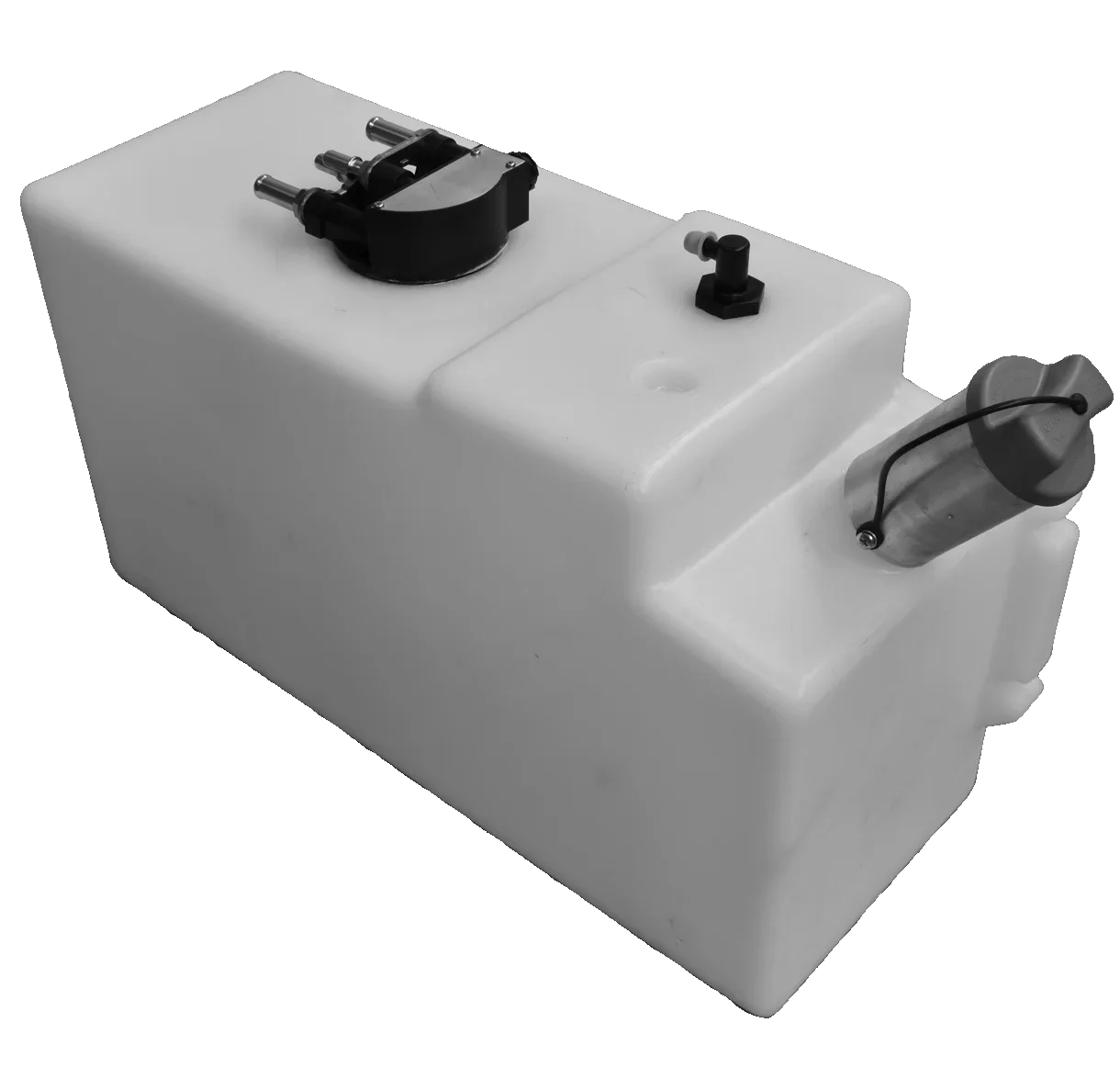

Our value proposition is deeply rooted in our vast experience in designing and creating exceptional components such as AdBlue tanks, airducts, battery houses, fuel tanks or wind shield wash tanks. These bus components are not just products; they are the lifeline of your vehicles, enabling them to function at their best. The use of the rotomoulding technique is a testament to our innovative approach, allowing us to design and manufacture parts that are precisely tailored to fit the unique requirements of buses. This method not only ensures that our components are of the highest quality but also facilitates the achievement of complex design shapes, crucial for optimizing space within vehicles.

Extremely durable in outdoor environments

Complex design to fit limited space

Highly customizable with meeting industry standards

The unique specifications

- Highly customizable

- The tanks are practically indestructible

- Integrations of functions

The unique specifications

- Plastic tanks are safe

- Safer than a steel tank in case of fire

- Materials suitable for contact with diesel

The unique specifications

- Possibility for large volumes

- Resistant to freezing

- Integrating components

Strong light-weighted rotomoulded bus parts

Strong, light-weight, and rotomoulded plastic bus parts represent the pinnacle of component design for electric buses and other vehicles. The durability and reduced weight of these components contribute significantly to vehicle efficiency, allowing for extended range and performance. Beyond their structural benefits, these parts are incredibly versatile and adaptable to the specific design needs of vehicle manufacturers, offering unparalleled functional and ergonomic integration without compromising on aesthetic appeal.

The ease of working with rotomoulded plastic bus parts is unmatched. Their ability to be moulded into virtually any shape or size means that customization is not just an option; it’s a standard. This flexibility ensures that components can be tailored to fit the unique designs and requirements of bus manufacturers, aligning perfectly with the vision of functionality, ergonomics, and visual appeal.

In conclusion, our premium rotomoulded plastic bus components offer a trifecta of benefits: unmatched strength and lightness, customizable to precise specifications, and cost-effective over their lifecycle. Opting for our bus components means choosing a path of innovation, efficiency, and sustainability. We stand ready to partner with vehicle manufacturers in their quest to deliver superior performance and design, reaffirming our position as a trusted leader in the provision of premium plastic components for the transportation industry. Let’s bring your idea to life! Contact us now!

Julia

Sales Manager

"A satisfied customer is the best business strategy of all"

your idea

to life. Start now!