Highly customizable plastic rotomoulded playground equipment

Rotomoulded plastic components are becoming an increasingly popular choice for manufacturers of playground equipment, due to their many benefits. With Rotovia, entrust your vision to our expertise in rotomoulding. Our knowledge and processes are dedicated to bringing your ideas to life. By choosing to let us produce your product by using our rotomoulding, your product undergoes a metamorphosis, becoming not only functional and aesthetic but also resistant to punctures and scraping.

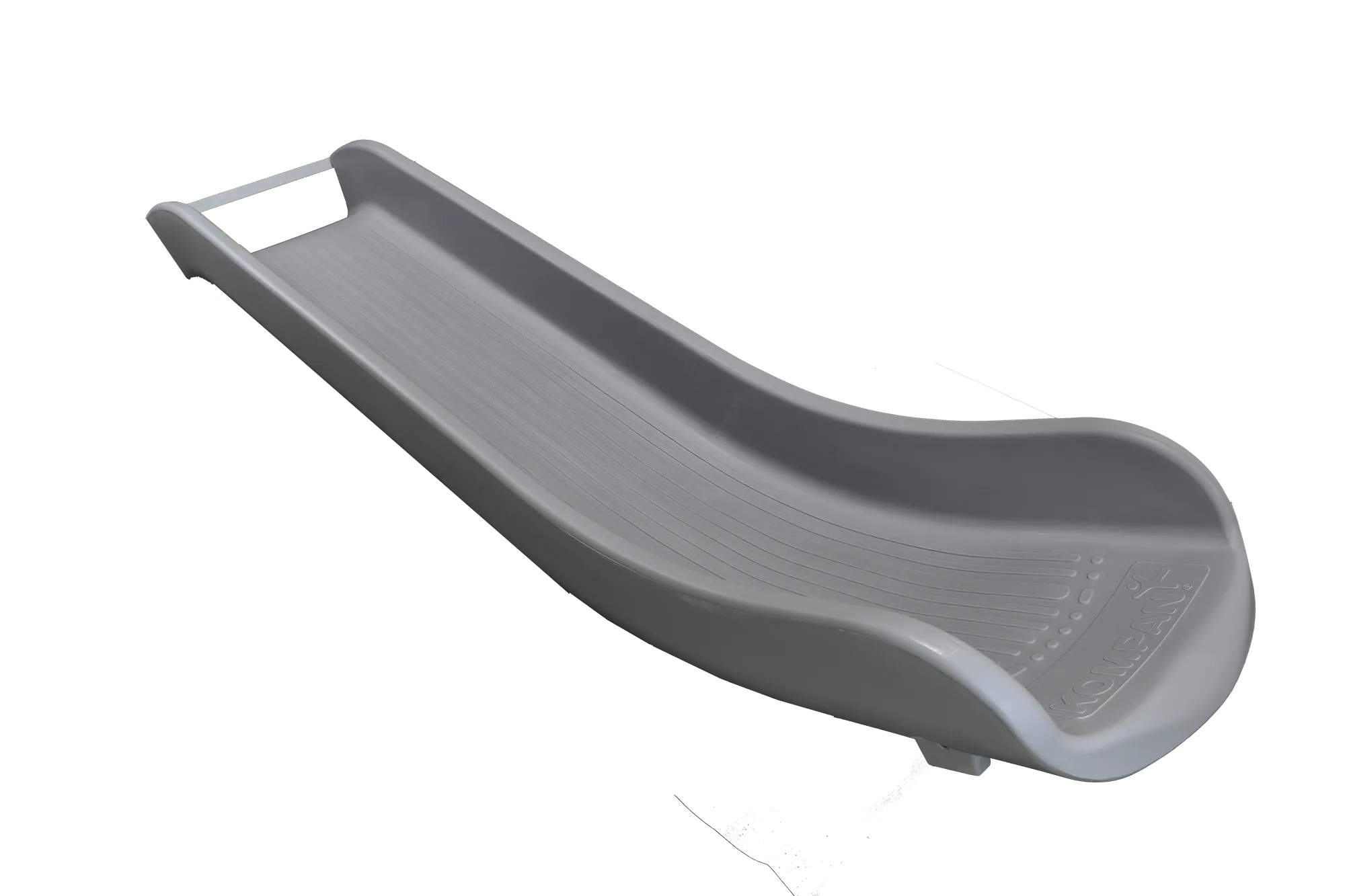

But there is more, the rotomoulded process is unique and allows us to turn your idea into the creation of large, complex, and hollow parts with a seamless design. All in all, this makes our process ideal for manufacturing playground equipment. Premium products produced by us, seamlessly merge functionality and aesthetics. Made with precision these components redefine durability and style in leisure. From seats to coolers or slides, each product is a unique idea turned into a fantastic product.

Another benefit of rotomoulded plastic parts is that they are highly durable and resistant to impact and weathering. This makes them ideal for use in playground equipment, which is exposed to the elements and subjected to heavy use by children and harsh outdoor weather. Rotomoulded plastic parts are also resistant to UV rays, which means they will not fade or become brittle over time.

Highly customizable

Functional and aesthetic

Resistant to punctures and scraping

Durable HDPE playground equipment

Rotomoulded HDPE playground equipment, such as seats for rotomoulded plastic swing sets and slides, boasts exceptional durability and resistance to punctures and scraping, making them ideal for rugged outdoor use. The secret lies in our rotomoulding manufacturing process, which involves heating and rotating a hollow mold filled with polyethylene or other plastic types resin until it evenly coats the complete component. This method creates a seamless, stress-free product with uniform thickness, eliminating weak points vulnerable to punctures.

The resulting structure is robust and resilient, able to withstand the rigors of outdoor play without succumbing to punctures or damage from scraping. The inherent flexibility of rotomoulded products also contributes to reducing the risk of permanent damage. This combination of materials and manufacturing techniques ensures that rotomoulded playground equipment not only provides hours of safe and enjoyable play but also withstands the challenges of the elements, maintaining its integrity and longevity over time.

Łukasz

Sales manager

"The harder, the better."

your idea

to life. Start now!