Modern solutions for the agricultural industry: rotationally moulded plastic components

Rotomoulding technology is transforming the agricultural industry by offering a range of innovative products ideal for use in various types of agricultural machinery. Rotomoulding, brings a number of benefits that are particularly relevant to the production of modern, efficient and durable agricultural machinery, such as tractors, harvesters, seeders or sprayers.

In today’s modern agriculture, where efficiency, productivity and durability are key, high-strength rotomoulded parts play an irreplaceable role. Thanks to them that agricultural machinery and equipment can successfully survive intensive use in a dynamic agricultural environment.

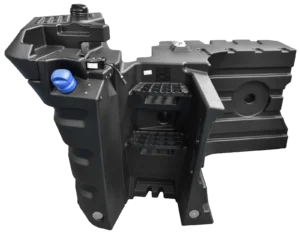

Plastic tanks such as fuel tanks, urea tanks, hydraulic oil tanks, Adbue tanks, sprayer tanks and other roto-moulded components used in agricultural machinery owe their high durability to the material from which they are made – high-quality polyethylene.

Modern solutions for the agricultural industry: rotationally moulded plastic components

Rotomoulding technology is transforming the agricultural industry by offering a range of innovative products ideal for use in various types of agricultural machinery. Rotomoulding, brings a number of benefits that are particularly relevant to the production of modern, efficient and durable agricultural machinery, such as tractors, harvesters, seeders or sprayers.

In today’s modern agriculture, where efficiency, productivity and durability are key, high-strength rotomoulded parts play an irreplaceable role. Thanks to them that agricultural machinery and equipment can successfully survive intensive use in a dynamic agricultural environment.

Plastic tanks such as fuel tanks, urea tanks, hydraulic oil tanks, Adbue tanks, sprayer tanks and other roto-moulded components used in agricultural machinery owe their high durability to the material from which they are made – high-quality polyethylene.

Complex plastic product shapes to meet agricultural industry standards

The rotomoulding process makes it possible to manufacture products of any shape, size and even complex details. As a result, we can produce unique tanks, mudguards, air ducts or other fittings for agricultural machinery with high durability and reliability. In addition, these products are highly configurable so that they can be perfectly adapted to the needs of specific agricultural machinery.

Our manufacturing process also allows additional tank components, such as hight qualty, to be added directly during product manufacture. These components are integrated into the product, this ensuring a high level of tightness, safety and performance. Rotomoulded tanks have full integration of components and functions.

Highly durable rotomoulded parts that meet the unique needs of modern farming

Polyethylene parts for agricultural machinery are manufactured in one piece, have no welds or joints, and are therefore characterised by robust construction and extreme durability. The uniform wall thickness of the plastic parts makes them resistant to mechanical damage, impacts, shocks, as well as high and low temperatures.

For agricultural machinery, which often operates in harsh field conditions, this feature is invaluable. Machine components such as housings, mudguards and tanks of all kinds are also UV resistant, which means that they do not degrade or crack over time. This makes them ideal for use in agricultural machinery that is exposed to the elements.

Plastic components for agricultural machinery support the idea of sustainability

Our rotomoulding process enables the creation of products with excellent strength and precision, while supporting the sustainable development of the agricultural machinery industry. Rotomoulded products made from polyethylene are easily recycled, helping to reduce waste and environmental impact.

Rotomoulded plastic components are not only an excellent technological solution, but also a strategic tool in the production of modern agricultural machinery. Their unique properties, such as strength, lightness, corrosion resistance and design flexibility, allow the creation of machines that are more efficient, durable, economical and comply with the latest environmental standards. By using rotationally moulded plastic components, the machines are becoming synonymous with quality, reliability and sustainability in the agricultural industry.

At Rotovia, we have been producing components for the agricultural industry for more than 20 years. Using our extensive know-how and our engineers’ expert knowledge of rotational moulding technology, we stamp out products of the highest quality, irreplaceable in agricultural machinery.

Contact us and let's bring your idea to life!