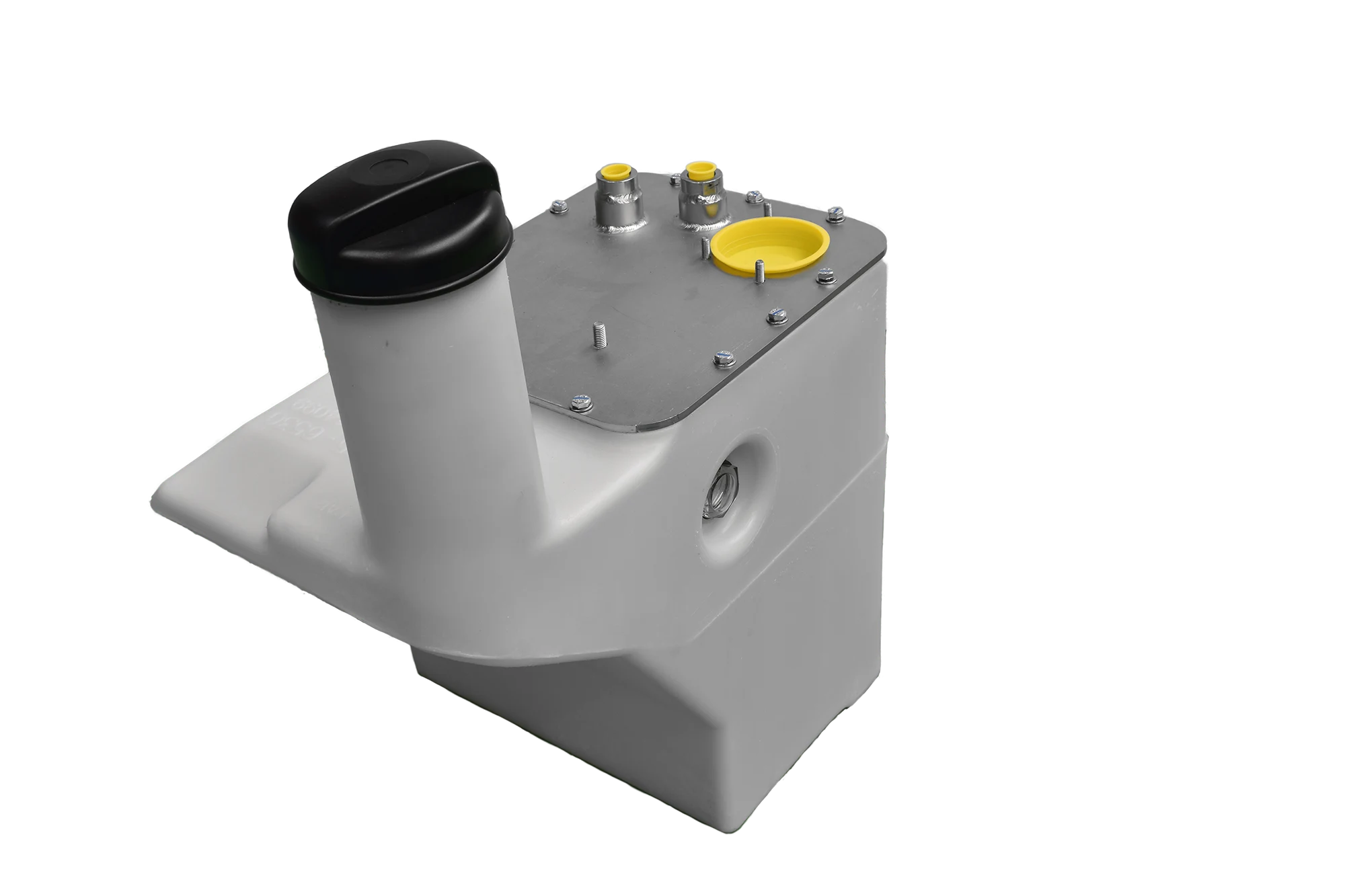

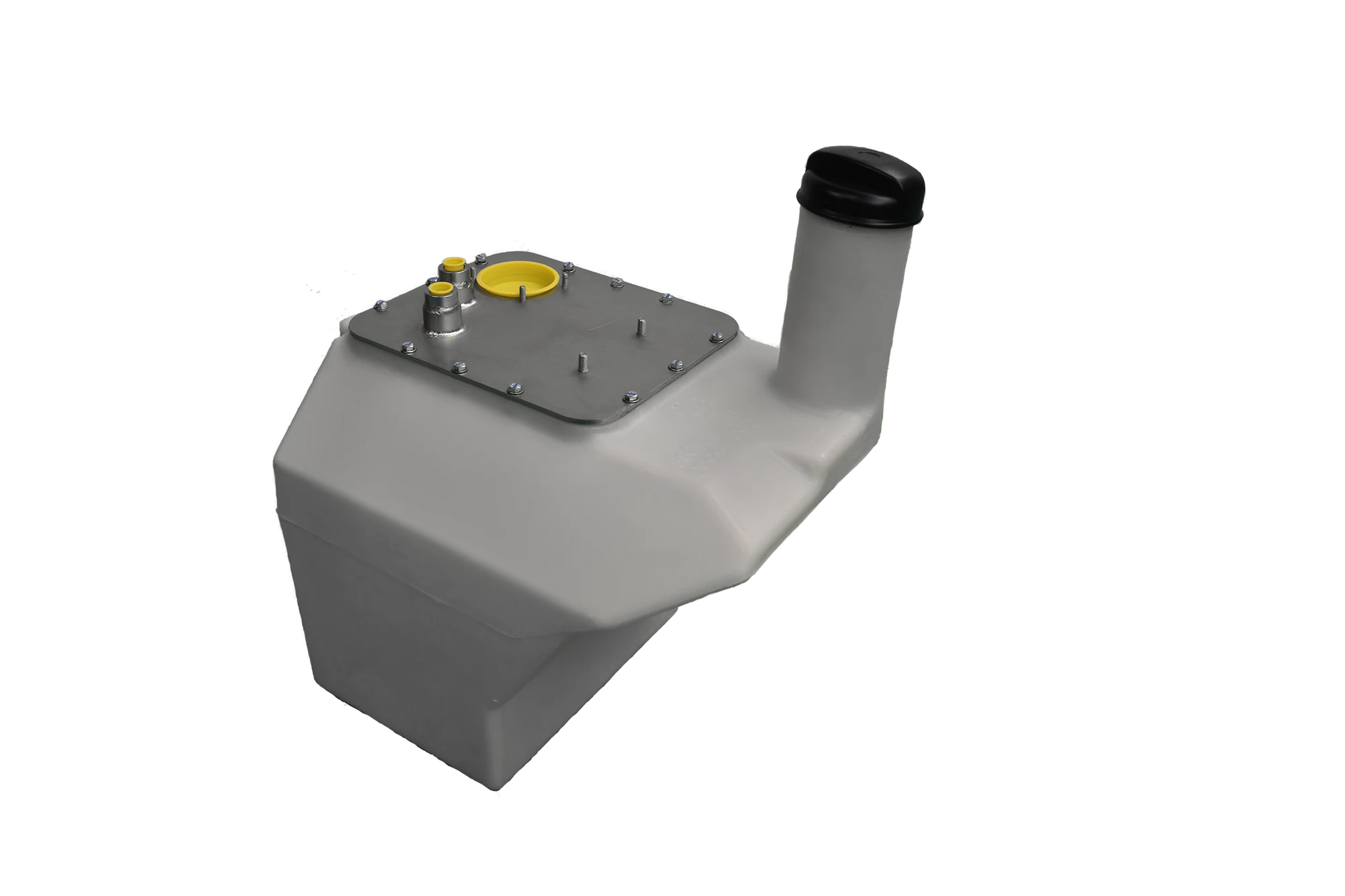

Harvester hydraulic oil tank with unique shapes

Rotovia has been active for many years in the agriculture market. One of the products we have been producing for our customers are harvester hydraulic oil tanks. Rotomoulded harvester hydraulic oil tanks are the best solution for harvester manufacturers looking to improve their products’ performance and longevity. The features of the rotomoulding tanks provide significant advantages that can help harvester manufacturers stay competitive and meet the demands and needs of their customers.

Using the rotomoulding process allows us to match the design created by manufacturers. This means that harvester manufacturers can create tanks and other products that are tailored to their specific needs and the requirements of their customers. The rotomoulding process also allows manufacturers to create tanks with intricate shapes and designs, which can help to improve the performance and functionality of the harvester.

Unique benefits of rotomoulded hydraulic oil tanks

Harvester hydraulic oil tanks have some unique benefits:

- Withstand harsh outdoor environments

- UV radiation stable material

- No degrading over time

- Long lasting

- No frequent replacement needed

- Resistant to chemicals and other harsh elements

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Integration of additional functions

Integration of additional functions is another key benefit of rotomoulded hydraulic oil tanks for harvester manufacturers. For example, manufacturers can integrate filtration systems, temperature sensors, and pressure gauges into the tanks, which can help to improve the performance and longevity of the harvester. Additionally, it is possible to integrate sensors and data collection systems to monitor the performance of the harvester, which can be used to improve the overall efficiency and productivity of the machine. If this all matches your idea, start now and let’s bring your idea to life! Contact us now!

Jean-Philippe

Sales Manager

"Trust is a major element: without it, no project will succeed"

your idea

to life. Start now!