Premium fan housings for wind turbines

At Rotovia, we recognize the critical role fan housings play in the renewable energy sector, specifically with wind turbines. Our commitment to sustainability drives us to offer premium fan housings that exceed the highest standards of reliability, durability, and performance. By incorporating advanced rotomoulding techniques, we ensure that our fan casings seamlessly integrate essential functions. This includes robust air inflow and outflow openings and inspection hatches for easy maintenance, all within a light-weight design that is both efficient and sustainable.

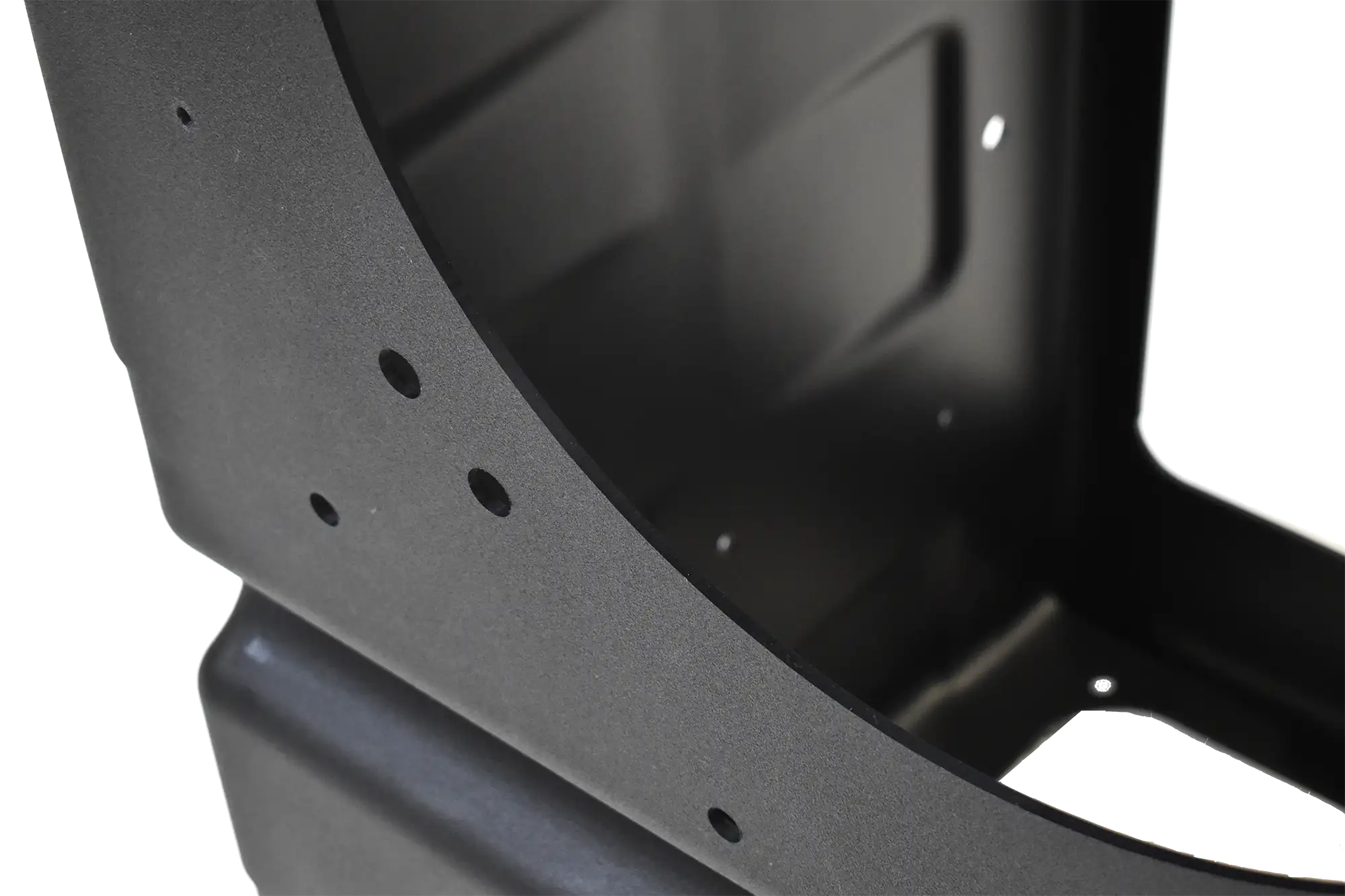

Durable rotomoulded fan housings

The resilience of Rotovia’s rotomoulded fan housings against vibrations and shocks is unmatched. Made from superior polyethylene and crafted through a pressureless process, these housings withstand the rigorous demands of the wind energy market. The absence of internal material stresses guarantees their longevity and reliability, making them a preferred choice for wind turbine applications. With thousands of our units successfully installed, our rotomoulded fan housings are proven to offer sustainable growth and optimal performance, reflecting our pledge towards environmental stewardship.

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Rotational moulding: ideal for wind turbine fan housings

Rotovia leads the way in rotational moulding, a technique pivotal for manufacturing fan casings and housings with unmatched precision. This process allows for the creation of large, yet light-weight, components essential for the renewable energy market. Our unique approach in collaborating with clients has led to the development of bespoke fan housings that integrate filter housings and air ducts, ensuring unparalleled performance. With Rotovia, customers benefit from durable, high-performance products that embody our commitment to premium quality and sustainable growth in the renewable energy sector.

For more details on wind turbine fan housings, contact us!

Jort

Account Manager

"Everything should be made as simple as possible, but not simpler"

your idea

to life. Start now!