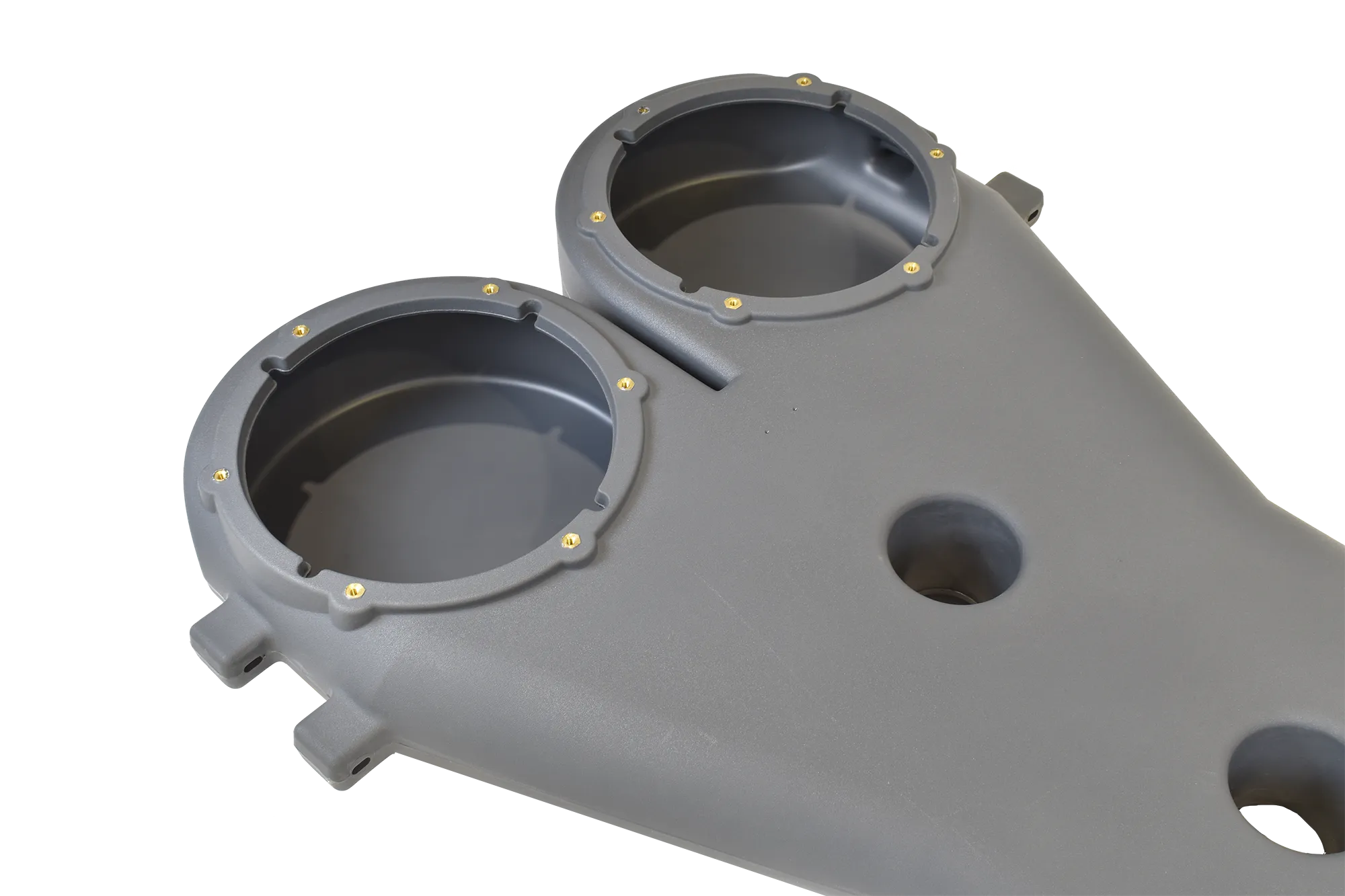

Cooling water tanks with complex shapes

There are various cooling tanks for turbines. One of the most popular choices is liquid coolant. In the past, liquid coolant tanks were often made of steel. This manufacturing method has its limitations. Steel tanks are often simply rectangular in shape. One of the design challenges is to find enough space for a tank of sufficient volume in a nacelle, which is packed with mechanical and electronic components. Because of this the space available for a cooling tank often has complex and awkward angles and shapes. This is where the exceptional benefit of rotational moulding comes in. It is well within our possibilities to design a tank with a complex shape so that the available space is used optimally, without minimizing quality or quantity.

Cooling tanks for turbines

During the life span of a wind turbine (the design life is often at least 20 years) a cooling water tank for wind turbines is subjected to pressure changes. This gives a fatigue load. This phenomenon is also prevalent with steel, which can still fail at a relatively low stress due to a changing load. This also applies to plastic. It is important that the maximum material tensions remain below a certain level so that the lifespan of rotationally moulded polyethylene tanks is no longer limited by fatigue. If an FEA analysis shows that the peak stresses are too high in several places, then due to the design freedom of rotational moulding, the design can often be improved easily by increasing radii, for example. Rotovia has a track record with various cooling water tanks that have been functioning without problems for many years in the wind turbine cooling system.

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

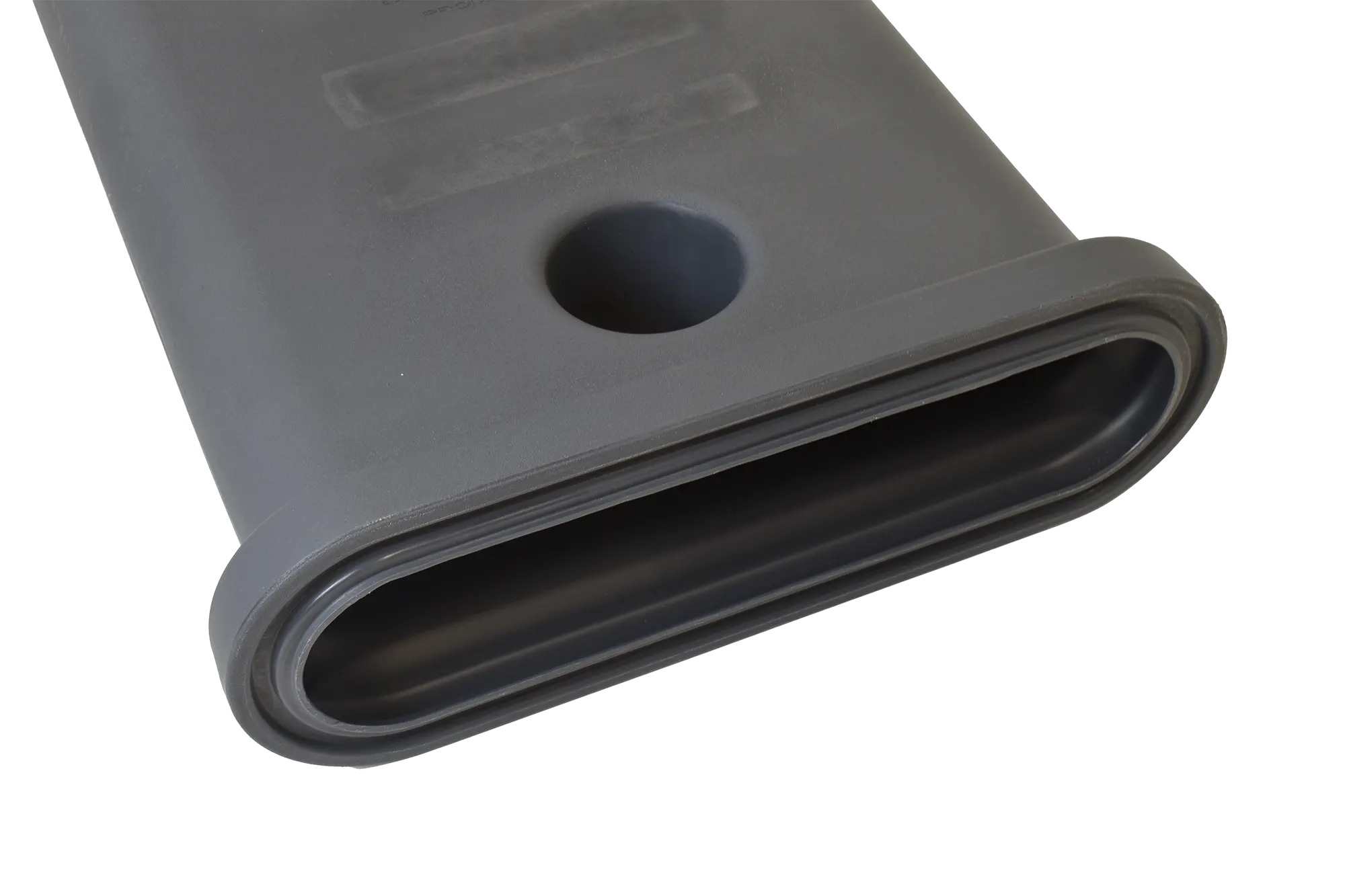

50% lighter compared to steel tanks

Save up to 50% compared to steel tanks. For example, a 125-liter rotationally moulded tank with a wall thickness of 8 mm polyethylene will weigh approximately 12 kg, depending on the design. The same tank in 3 mm sheet steel will weigh 31 kg, more than twice as much. The lower weight of a rotationally moulded tank has several advantages. For example, the product is easier and safer to handle during the assembly of the wind turbine. The lower weight also gives an advantage in logistics costs, which are very relevant for the wind turbine industry because they are transported all over the world. Less material use also means lower costs. In addition, polyethylene is fully recyclable, making it a sustainable solution, fully in line with the objectives of wind. Let’s bring your idea in the renewable energy segment to life! Contact us now!

Jort

Account Manager

"Everything should be made as simple as possible, but not simpler"

your idea

to life. Start now!