Extremely durable rotomoulded hydraulic oil tanks

Rotovia is been producing premium and sustainable solutions for many years in the renewable energy market. One of the products is hydraulic oil tanks for the wind energy segment. There are several material options for making plastic hydraulic oil tanks, depending on the maximum oil temperature. If the operating temperature is a maximum of 75 degrees for a long time, polyethylene can be used. At higher operating temperatures, alternatives are available such as cross-linked polyethylene (up to 85 °C), polypropylene (up to 90 °C), and nylon (up to 100 °C). The short-term peak temperature, assuming 0.5 hours per day, can be about 10 °C higher than the long-term operating temperature. In general, hydraulic systems work with an operating oil temperature of 60°C and a maximum temperature of 80°C. This makes the use of a rotomolded hydraulic oil tank not only possible but recommended as well.

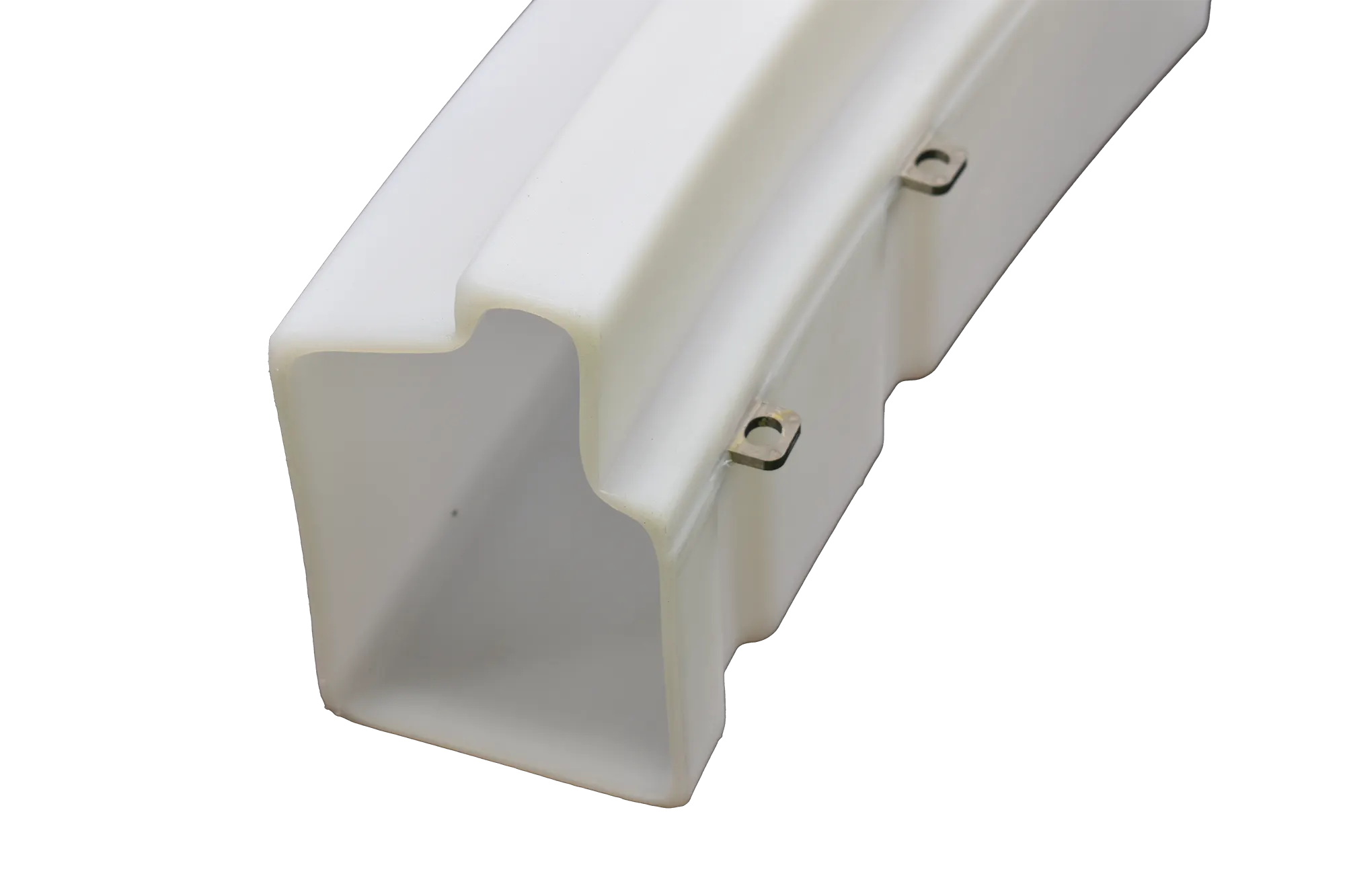

Hydraulic oil reservoir tanks with complex shapes

The nacelle of a wind turbine is a small compartment, containing many different components. In this space, there are structural components such as steel beams and profiles, cable ducts, floors and shutters. This makes it difficult to find enough space for a hydraulic oil reservoir tank with sufficient volume capacity. Alternatively, a simple rectangular steel tank is not practical either. To use all available space optimally, a hydraulic oil tank with a complex, custom design is required. In rotational moulding, a complex design is often beneficial and gives an advantage because this design makes the tank stiffer. The design criteria are not so much complexity, but whether the tank can be removed from the mould. However, a mould for rotational moulding does not necessarily have to be two parts but can consist of several parts, so that complicated shapes can also be manufactured.

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Save weight with plastic hydraulic oil tanks

A steel tank is assembled from several metal plates, especially if the design deviates from a simple rectangular shape. These plates are cut and set and then must be welded air-tight along all seams. In addition, durable stainless steel must be used. If a standard type of steel is used, the tank must be coated inside and outside against corrosion. The combination of these elements makes the tanks heavy and expensive. With rotational molding, we can produce single-piece hollow hydraulic oil tanks. Of course, the plastic material does not corrode, so no secondary treatment is necessary. Threaded inserts can also be cast in the process which is a huge benefit for installing. With these lightweight hydraulic oil tanks, you could optimize the space in the nacelle of your wind turbines and make installing components much easier. Contact us now to bring your plastic idea to life.

Jort

Account Manager

"Everything should be made as simple as possible, but not simpler"

your idea

to life. Start now!