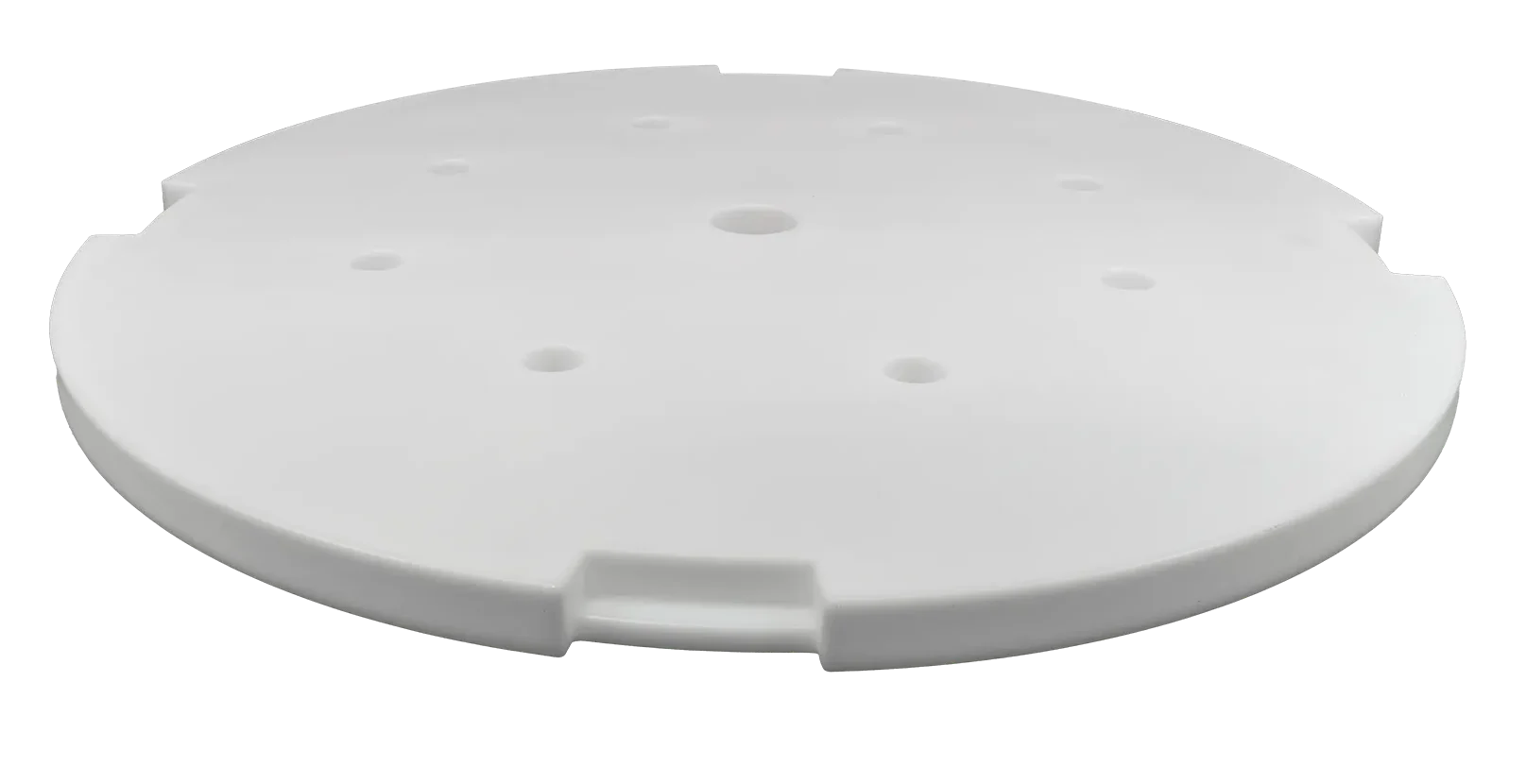

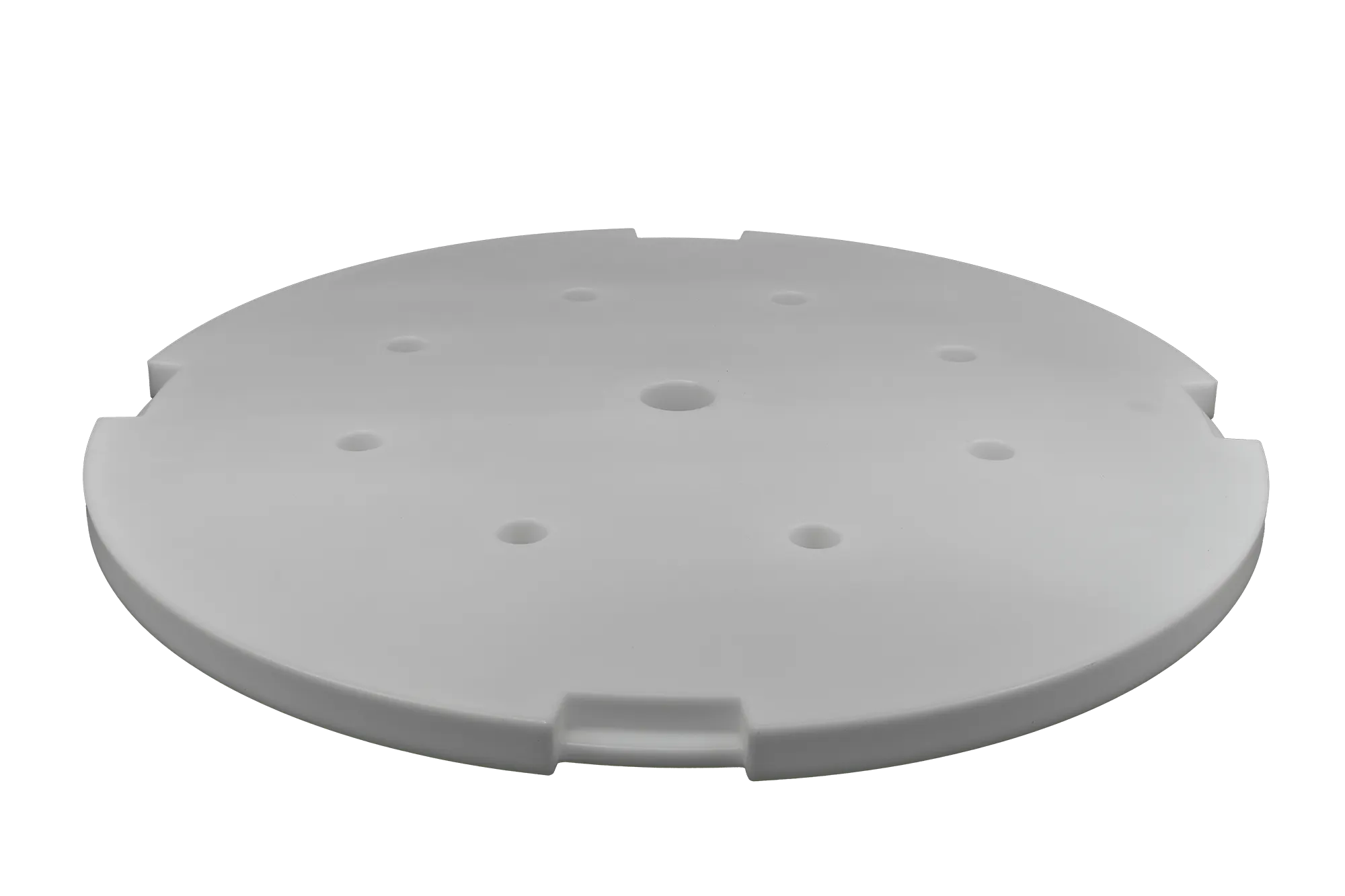

Rotomoulded damper tanks

Rotomoulded plastic parts manufactured by Rotovia are perfect for the renewable energy industry. Our rotomoulding technology allows us to produce plastic parts designed to meet the specific needs of our customers, such as damper tanks. Our damper tanks are of the highest quality, meeting all the necessary standards. The materials we use to manufacture our products are extremely durable, so the final products for the wind energy industry are characterized by excellent strength and reliability in long-term use. Our rotational moulding process enables us to manufacture a product in one piece. This unique combination provides manafacturers of damper tanks with an ideal solution for the wind energy industry.

Unique benefits of rotomoulded damper tanks

The rotomoulded damper tanks that Rotovia produces come with various unique benefits:

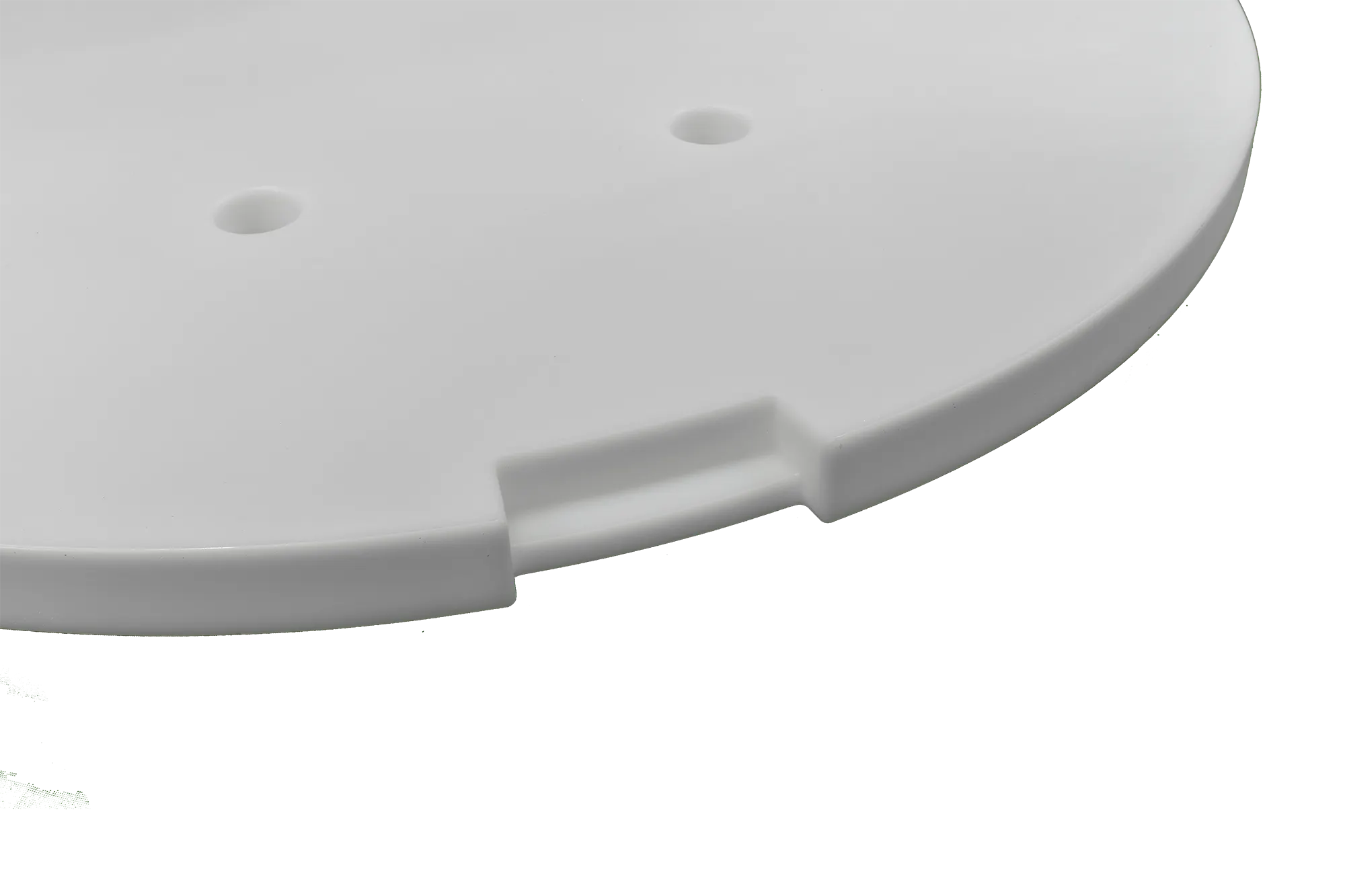

- The product shape is designed to increase resistance to external forces and loads

- The material is selected to handle a long lifetime in changing conditions

- Excellent burst and tear resistance

- Insensitivity to low and high temperatures

- The tanks are corrosion-proof

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Polyethylene damper tanks, perfectly resistant to external loads

Our rotomoulded damper tanks are characterized by unique benefits, including an extremely important one: their excellent robust structure and strength, which makes the tanks resistant to any damage, tearing or ripping of the tank surface. Another important benefit of damper tanks is their unique shape, which has been designed in such a way as to maximize resistance to forces and external loads. The high-quality polyethylene used to manufacture the damper tanks makes them highly resistant to impacts and shocks. Another unique advantage is that they are corrosion-proof and exceptionally resistant to both low and high temperatures. The polyethylene damper tanks manufactured in the rotational moulding process are the best products for such an innovative and demanding sector as the wind energy industry. Let’s bring your idea to life! Contact us now!

Jort

Account Manager

"Everything should be made as simple as possible, but not simpler"

your idea

to life. Start now!