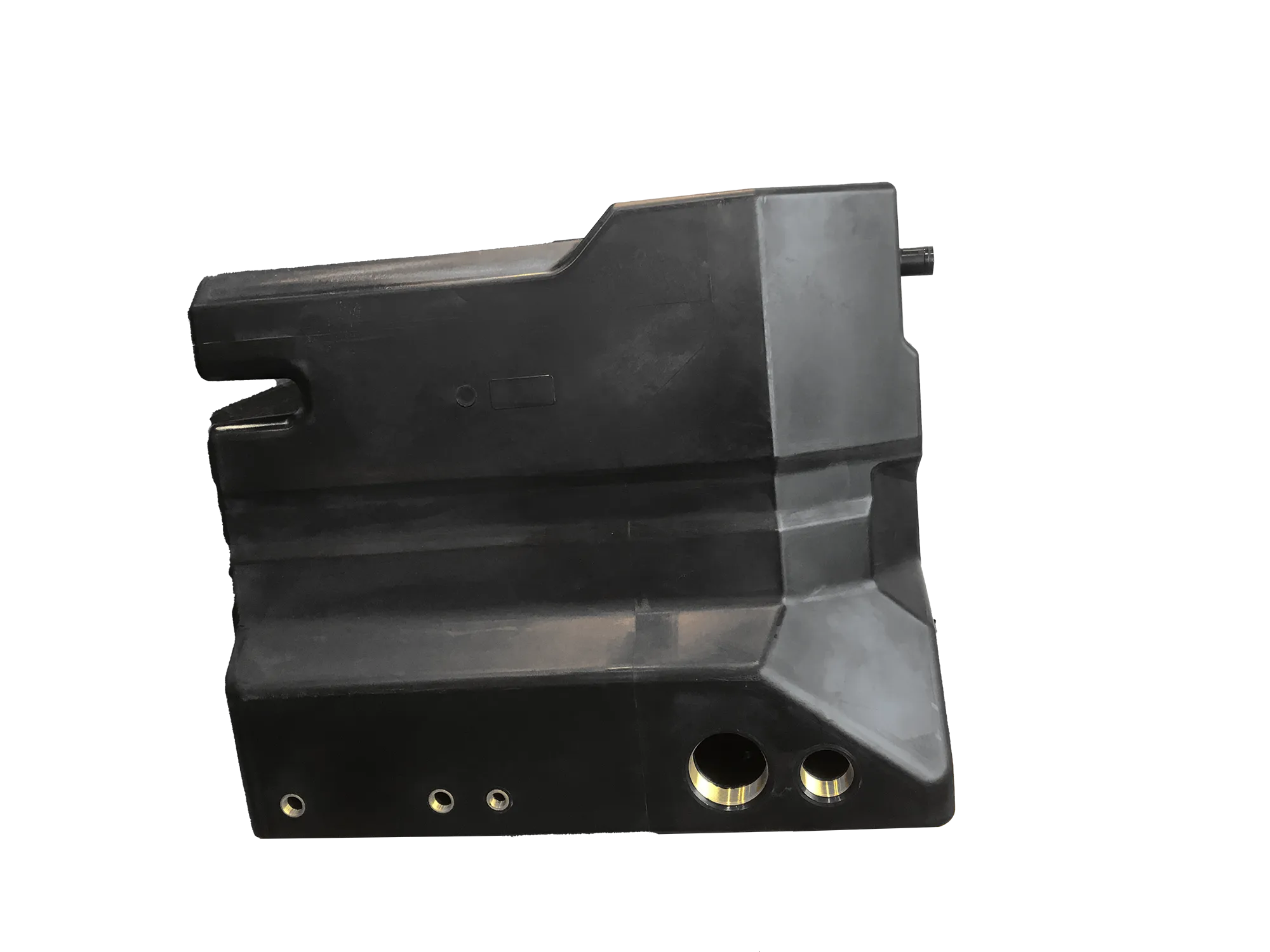

Rotomoulded hydraulic oil tanks for tractors

Rotomoulded hydraulic oil tanks for tractors have emerged as a revolutionary solution in the agricultural industry, offering many benefits that make them indispensable for modern farming equipment. These tanks have gained prominence for their exceptional durability in outdoor environments, ability to adopt complex shapes to meet industry standards, and seamless integration of components and functions.

One of the key advantages of rotomoulded hydraulic oil tanks is their unparalleled durability in outdoor environments. Traditional metal tanks are susceptible to corrosion, rust, and damage from exposure to harsh weather conditions. In contrast, rotomoulded tanks are crafted from high-density polyethylene (HDPE), a rugged and weather-resistant material. This makes them ideal for withstanding the rigors of agricultural operations conducted in diverse and often challenging outdoor settings.

Tailored to your needs

Rotomoulded hydraulic oil tank for tractors can be designed and manufactured to meet specific requirements and to fit into limited spaces in the tractors:

- Threaded connections by immoulded inserts

- Complex design to maximize volume for available space

- One-piece seamless leak-tight tank

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Extremely durable in outdoor environments

The rotomoulding process itself contributes significantly to the durability of the tanks. Rotational moulding involves heating plastic resin in a mould that is rotated on multiple axes. This creates a seamless, stress-free product with uniform wall thickness, eliminating weak points and vulnerable seams. The resulting tanks exhibit strength, ensuring they can endure the demanding conditions encountered during tractor operation in the field.

Additionally, the rotomoulding process allows for the creation of hydraulic oil tanks for tractors with complex shapes, meeting and often exceeding industry standards. Agricultural machinery design can be intricate, requiring tanks to fit into tight spaces and accommodate specific configurations. Rotomoulding enables the production of tanks with intricate geometries, ensuring a precise fit within the limited spaces available in tractors. This versatility in shaping is essential for meeting the evolving design requirements of modern agricultural equipment.

Seamless functionality

The complex shapes achieved through rotomoulding are not merely about aesthetics; they are crucial for optimizing the functionality of hydraulic oil tanks and other tanks such as fuel tanks and UREA tanks. These tanks often need to integrate seamlessly with other tractor components and systems. The ability to design tanks with custom shapes ensures a perfect fit within the overall machinery framework. This contributes to the efficiency of the tractor, enhancing its performance and minimizing the risk of malfunctions or leaks.

Furthermore, rotomoulded hydraulic oil tanks boast full integration of components and functions. The tanks can be manufactured with built-in features streamlining the installation process. This eliminates the need for additional components and reduces the likelihood of compatibility issues. The result is a fully integrated hydraulic system that enhances the overall reliability and performance of the tractor.

Jean-Philippe

Sales Manager

"Trust is a major element: without it, no project will succeed"

your idea

to life. Start now!