The most accurate 3D scanning services for your premium products

At Rotovia, we offer a comprehensive 3D scanning service from physical scanning to post-processing. Our scanning service accurately measures 3D rotomoulded products, providing extremely accurate measurement data. We also focus on advanced post-processing, eliminating any errors or inaccuracies. The end result of our work is finished measurement reports that provide our clients with a full view of the information collected.

Our 3D product scanning service is an indispensable tool for improving design processes. Thanks to our comprehensive service, our customers gain not only precise 3D models of their custom moulded products, but also the possibility to use the collected information in the design process or quality control.

Short-range scanning service for custom moulding products

Our short-distance scanning service includes the generation of a digital model of all product sizes in a wide range of surface finish, gloss, reflectance, texture, colour and levels of intricacy or detail options, and, using accurate and efficient scanning technology, generates ready-to-use part-mesh-to-STL files in minutes.

3D scanning is an excellent tool for part-to-CAD inspection, enabling precise comparisons between physical specimens and design data. This is important for ensuring compliance with design intent and eliminating potential deviations or manufacturing errors.

We also provide support in the area of 3D digital protection and 3D archiving. With product scanning, complete product documentation can be compiled with all measurements in a digital version, which facilitates storage, protects against information loss and facilitates data management processes. The 3D scanning service we offer also enables an in-depth analysis of competing products. By comparing geometric details, you can identify the strengths of your own products and areas that can still be improved.

Reverse engineering - a new dimension in design

Our experience and extensive knowledge in the area of 3D scanning not only includes the ability to accurately record product measurements, but also the use of advanced reverse engineering. With this service, we are able to convert existing products into accurate 3D models. This process is indispensable in the absence of design documentation or the need to modify existing products.

Not only can we record the structures of a given product, but we can also influence the refinement process of custom-moulded products. The use of reverse engineering also allows us to modify selected product parameters, optimise and enhance products with additional features.

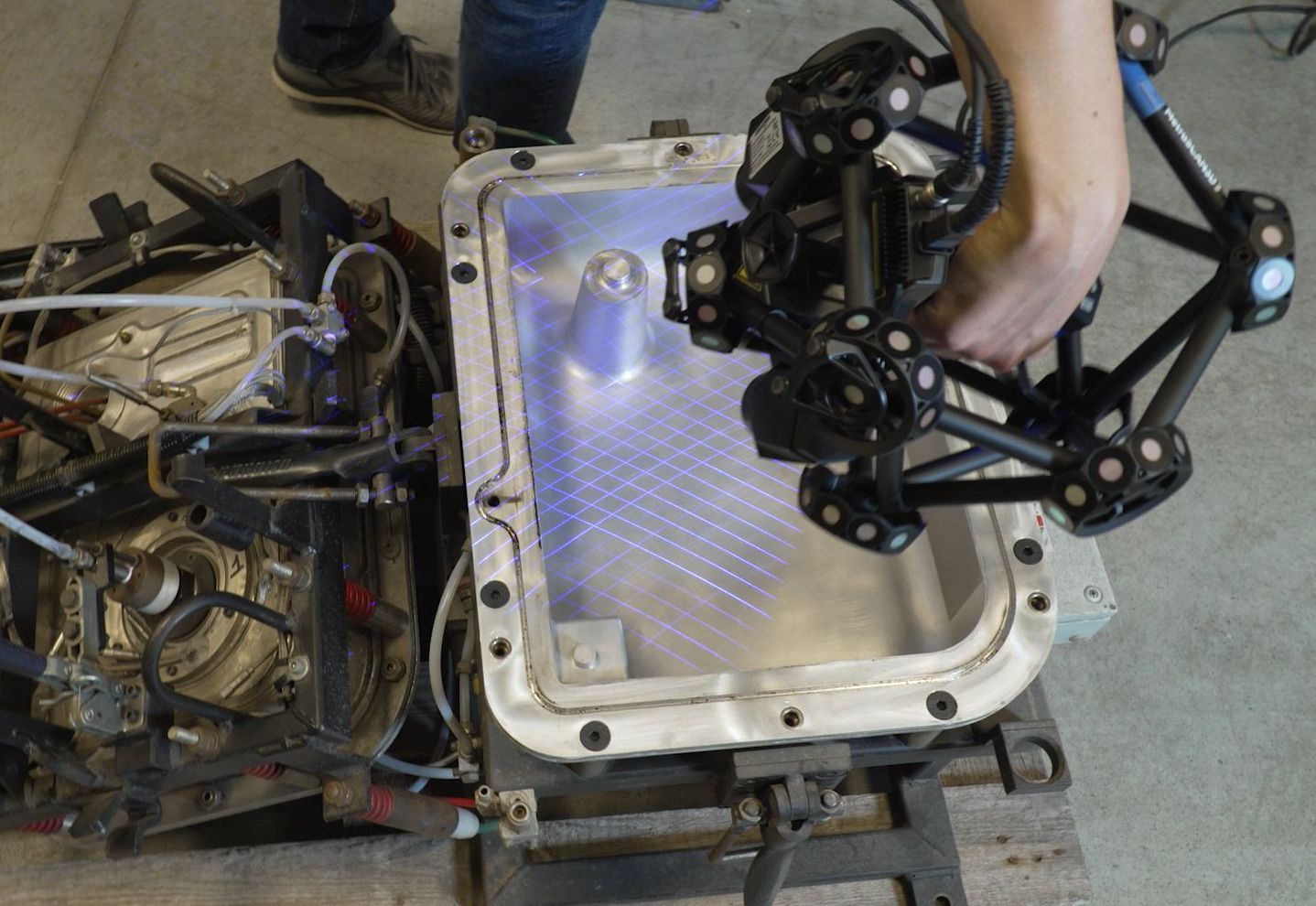

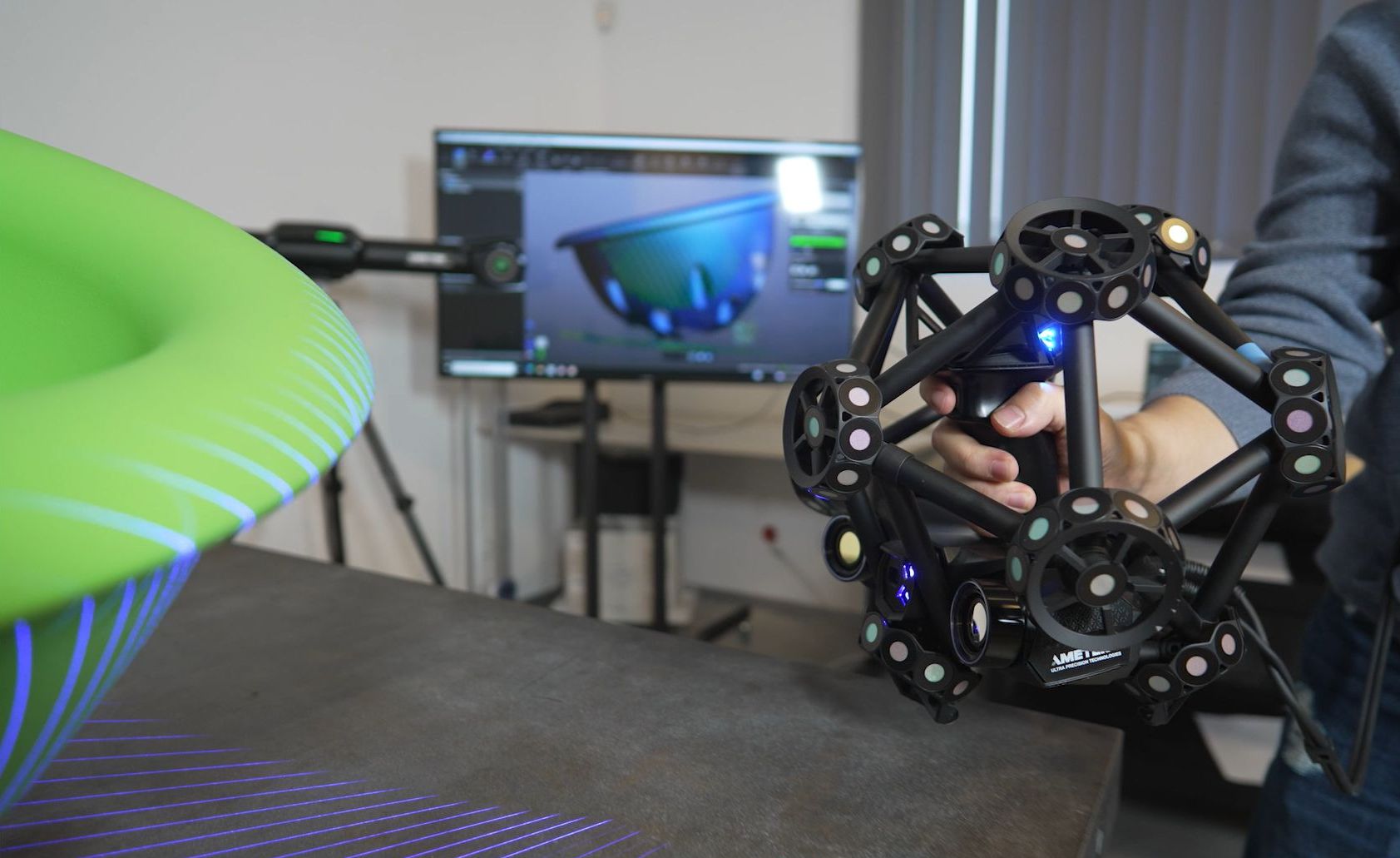

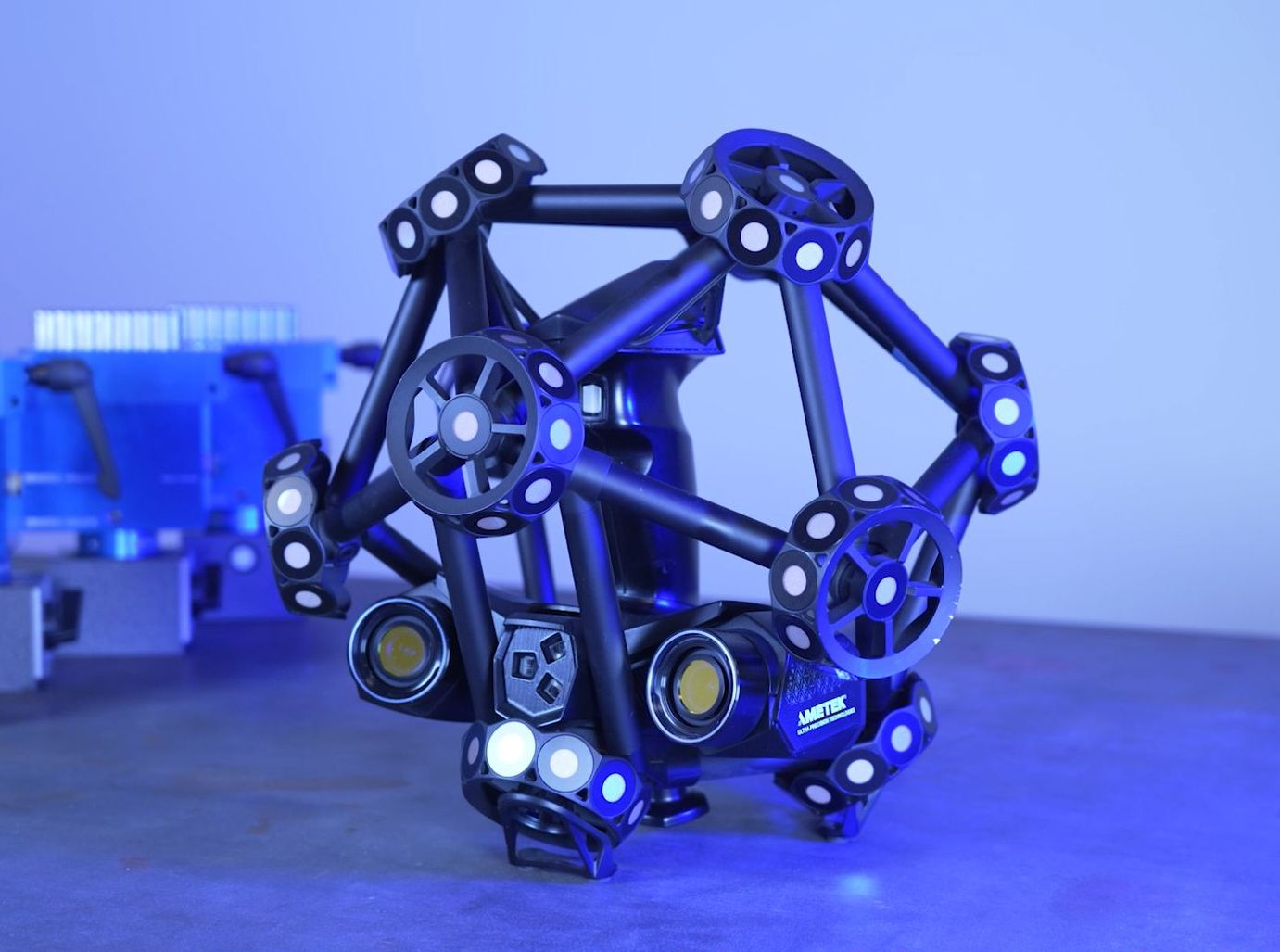

Accuracy and precision of 3D scanning with the highest quality scanner

The 3D scanning service we provide is based on a state-of-the-art scanner that offers unique features. Thanks to its large scanning area and 15 laser crosses, it ensures precise reproduction of every detail. The incredible scanning speed,1.800.000 measurements per second, guarantees a fast and efficient process, reducing the time required to obtain complete data on the scanned product. The ability to visualise in real time, allows the collected data to be accessed and analysed immediately. This allows us to assess the quality of the scanned components in real time and respond quickly to any process adjustments needed.

Rotovia’s 3D scanning service, using our high-end 3D scanner, makes it possible to validate products, tools or instruments before they are released, significantly reduces the time spent on measurement activities, and improves the quality of measurements compared to other scanning equipment.

Comprehensive 3D scanning services

Our comprehensive 3D scanning service includes:

- Product scanning – full scan of each product small/large in a very short time to support product development and design.

- Tool or jig scanning – verification of the equipment on delivery and periodic checks for wear&tear.

- Jig / fixtures / gauges real-time calibration – live verification of the equipment allowing fast adjustments towards final CAD.

- Preparation of a digital “master sample” – saving space and preserving the dimensions of the product.

- Support for Quality Departments with accelerated measurements for quality assurance processes SPC or PPAP.

- Maintenance purposes – part or machine wear&tear control.

Rotovia - your reliable partner in the production of premium products

Our 3D scanning services will provide you with accurate measurement data of your products, but also open the door to new design opportunities. 3D product scanning is a comprehensive solution that translates into effective project management, innovation and competitiveness in the market.

Take advantage of our the most accurate 3D scanning services to optimise your custom moulded products.

Contact us!your idea

to life. Start now!