Colouring and grinding in material preparation rotomoulding

Colouring and grinding in the rotational molding process are two important steps in the material preparation for rotomoulding. The plastic resin starts as granules: round balls of resin that are about 3 mm in diameter. To prepare this material for the rotomoulding process, the granules need to be reduced in size into particles below 600 mu. This fine powder can be blended with pigments or other additives to create specific properties and to colour the resin.

Grinding

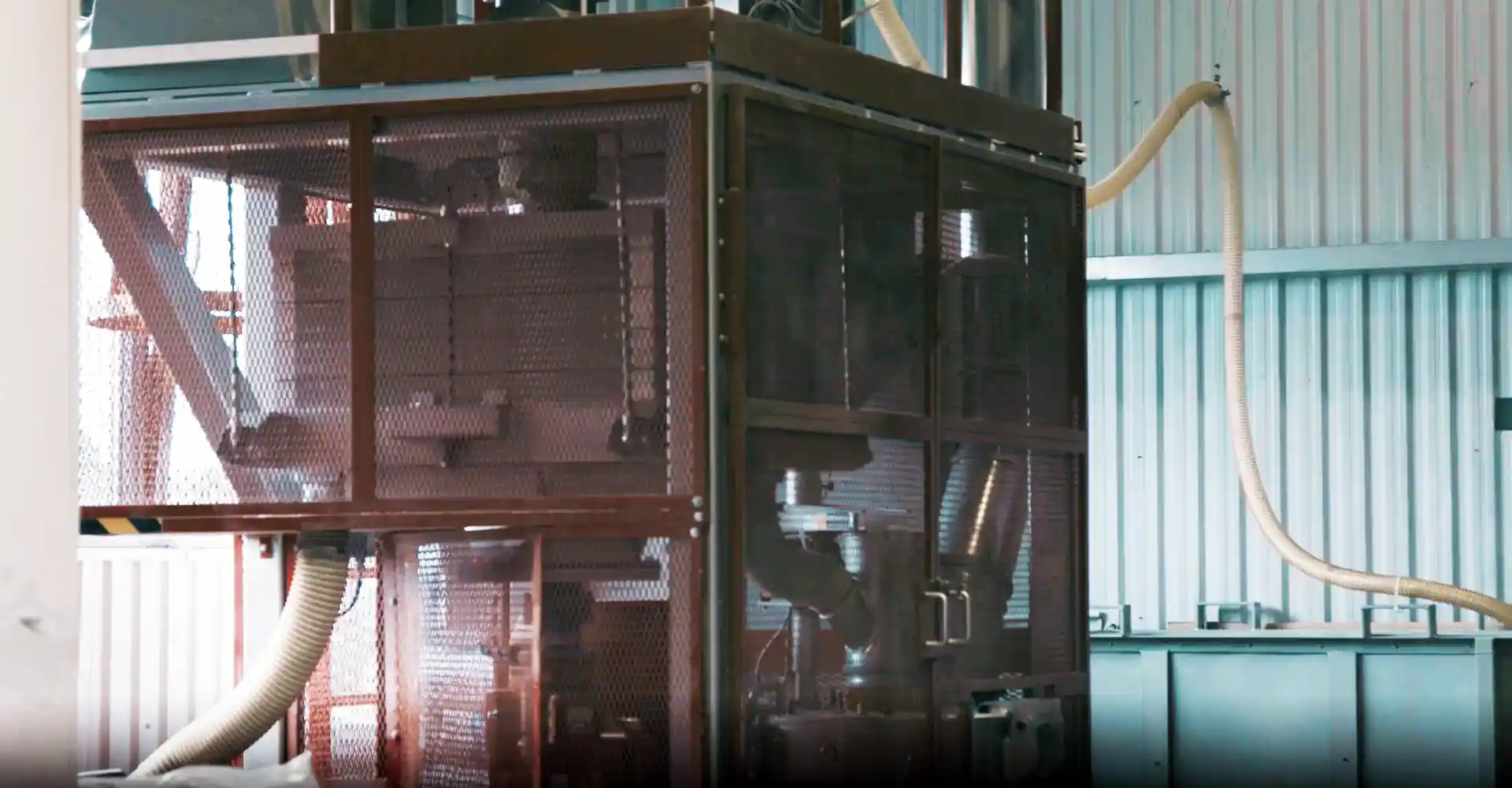

Grinding is the material preparation process of reducing the size of the plastic pellets to a powder. This is done using a grinder, a special pellet grinding machine that uses high-speed rotary blades to chop the pellets into smaller pieces. By using pellet grinding machines in material preparation rotomoulding, the quality of the raw material can be controlled by carefully monitoring the grinding process. In this way, any imperfections that could adversely affect the final product can be eliminated.

The grinding process is important because the resulting powder must have a defined particle size distribution as well as specific particle shapes. Good grinding pellets ensures that the plastic powder is of the correct size and shape, so it melts into the solid and consistent wall during the rotomoulding process. Appropriate griding pellets is necessary to achieve finished products of good quality.

Dry-blending process

The dry-blending process can be used in the preparation of plastic powder for the rotomoulding process. It involves mixing the plastic resin with other ingredients, such as pigments, fillers, stabilizers, and UV inhibitors, in a dry form. This can be done using a dry-blending machine, which typically includes a mixing chamber, an auger, and a discharge chute.

The ingredients are added to the mixing chamber, where they are mixed by the auger, and then discharged through the chute. The dry-blending process can produce a consistent and homogenous mixture, required for achieving a consistent colour and other properties in the finished product. The blended powder can be used for rotational moulding.

Compounding in material preparation process

Plastic compounding process is mixing plastic resin with various ingredients such as pigments, anti-oxidants, stabilizers, and UV inhibitors. This is done using a compounding machine that typically includes a mixing funnel, an extruder, and a pelletizer. The plastic resin is added to the mixing funnel and mixed with other ingredients using mechanical agitation. The mixture is then fed into the extruder where it is melted and homogenized under high pressure. The extruded mixture is then pelletized and cooled, forming small plastic pellets. The compounded and pelletized material now is ready for the next processing step which is grinding, one of the essential steps for the material preparation rotomoulding.

Through compounding, various types of plastic compounds can be created, each with specific properties such as colour and UV resistance, depending on the ingredients used. The plastic compounding process is also useful when it comes to using recycled materials. Compounding will homogenize the recycled plastic and prepare it for the next lease of life with the right level of antioxidants and UV inhibitors. Compounding aims for the right material preparation rotomoulding

Micropellets

Micropellets, also known as micro-pellets or mini-pellets, are small plastic pellets that can be directly used in the rotomoulding process. Micropellets are also made by compounding granules and then pelletizing and cooling. The big difference with regular compounding is the pellet size. These pellets are much smaller in size than traditional plastic pellets, with a diameter well below 1 mm. There is no need for the grinding step otherwise required to reduce size of granules.

The small pellets have a consistent size and shape and are also more compact: their “bulk density” is lower compared to regular powder. When used in the rotomoulding process they show very good flow characteristics: the micropellets roll into the finest details of a mould and through the thinnest areas possible in rotational moulding. Overall, micropellets can be beneficial for small, intricate technical mouldings, with high part definition.

Check out the next step in the rotational moulding process!

Loading process rotomoulding

Jean-Philippe

Sales Manager

"Trust is a major element: without it, no project will succeed"

your idea

to life. Start now!