Demoulding rotomoulding as the next step

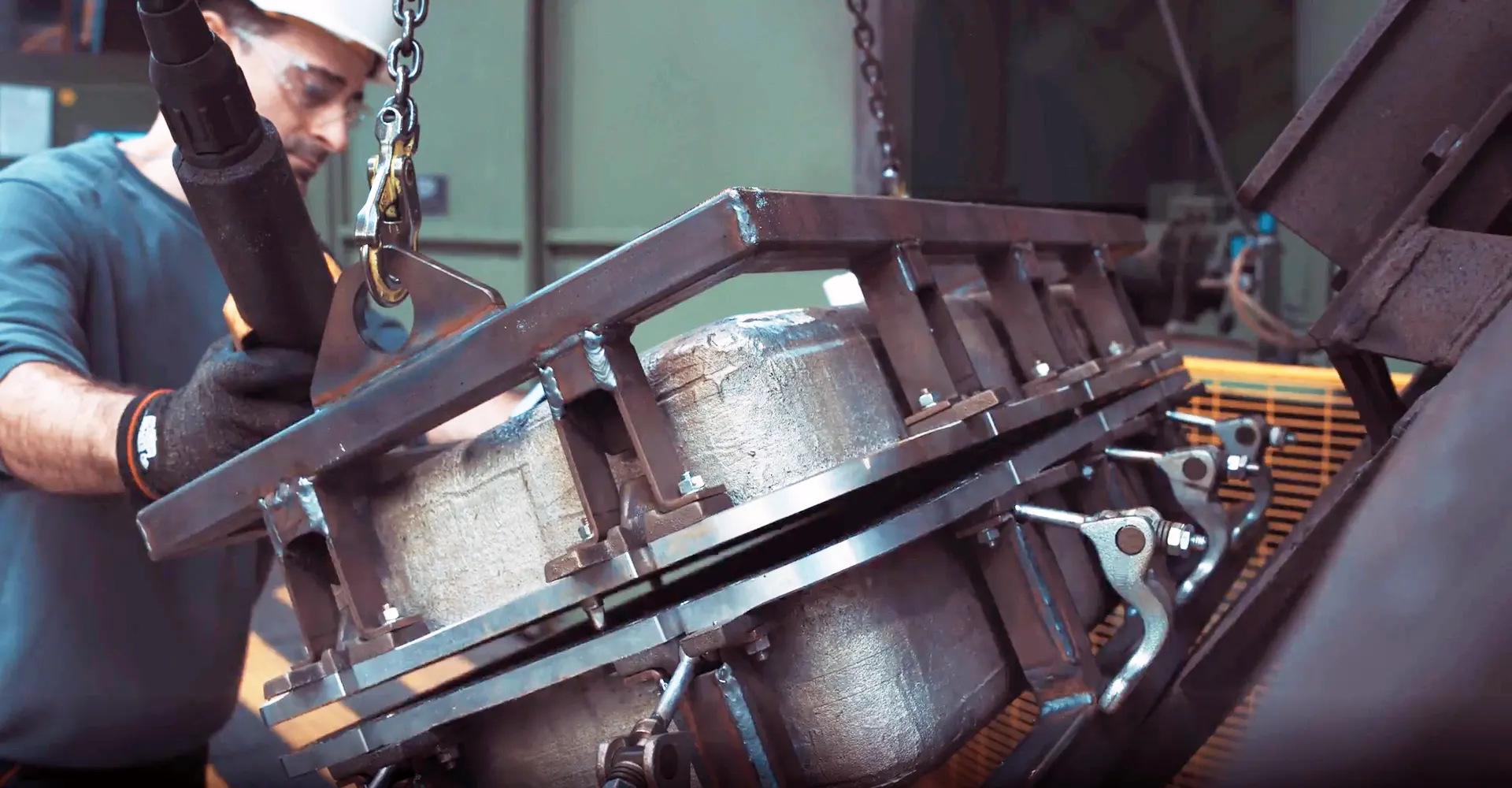

Demoulding rotomoulding, also known as unloading, involves removing the finished product from the mould after the cooling phase. The process starts with the alignment of the mould after the rotation phases. The inserts held in the mould are released, the clamps are released, allowing the first part of the mould to be removed.

If the mould consists of multiple parts, each part is removed so that the rotomoulded part can be removed from the base. Depending on the shape of the part being moulded, injectors or external tools may be used to assist in removing the product from the mould.

The demoulding process requires precision and attention to ensure safe and effective removal of the product, while minimising the risk of damage to the mould and the final product. The product removed from the mould is ready for further finishing and assembly processes. The demoulding rotomoulding process is not only a technical step, but also one of the steps that determines the excellent quality of any manufactured product.

Controlled release of product from the mould

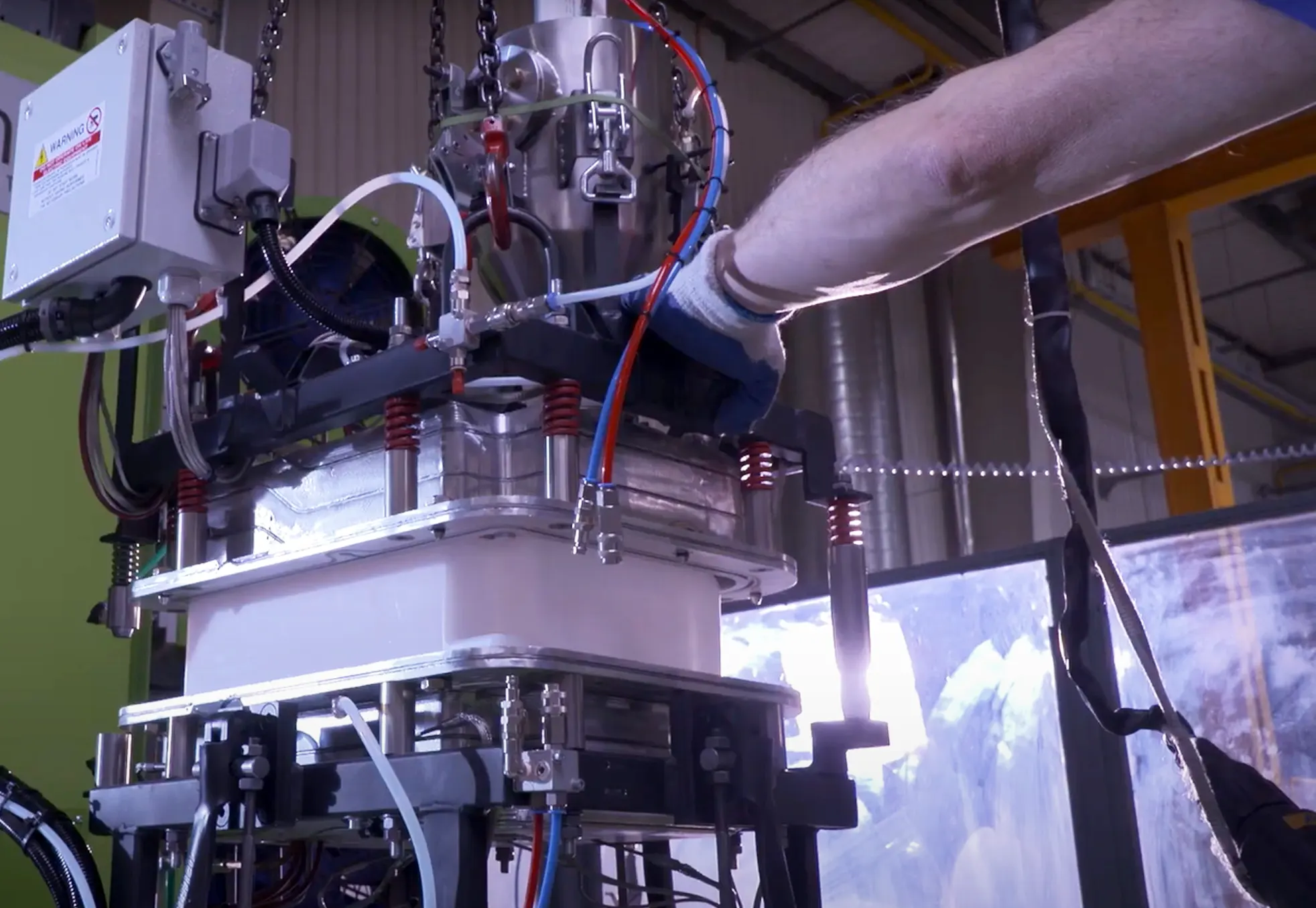

In order to ensure controlled release of the finished product from the surface of the rotational mould, special anti-adhesive agents are used. These substances are applied as a coating on the inside of the mould, serving to regulate the release of the finished product. Their function is to maintain the balance between premature release of the product and its potential sticking to the mould. Premature detachment of the resin inside the mould can lead to non-uniform cooling of the product or improper curing, which can result in deformation. In turn, parts remaining stuck to the mould can lead to damage during the removal process.

Therefore, understanding and properly controlling the release of resin from the mould plays an important role at this stage of the rotational moulding process, also known as demoulding rotomoulding. Through the proper use of anti-adhesive agents and monitoring of the de-moulding process, we can ensure not only high quality, but also productivity and repeatability of the plastic parts produced.

The final cooling of the de-moulded product

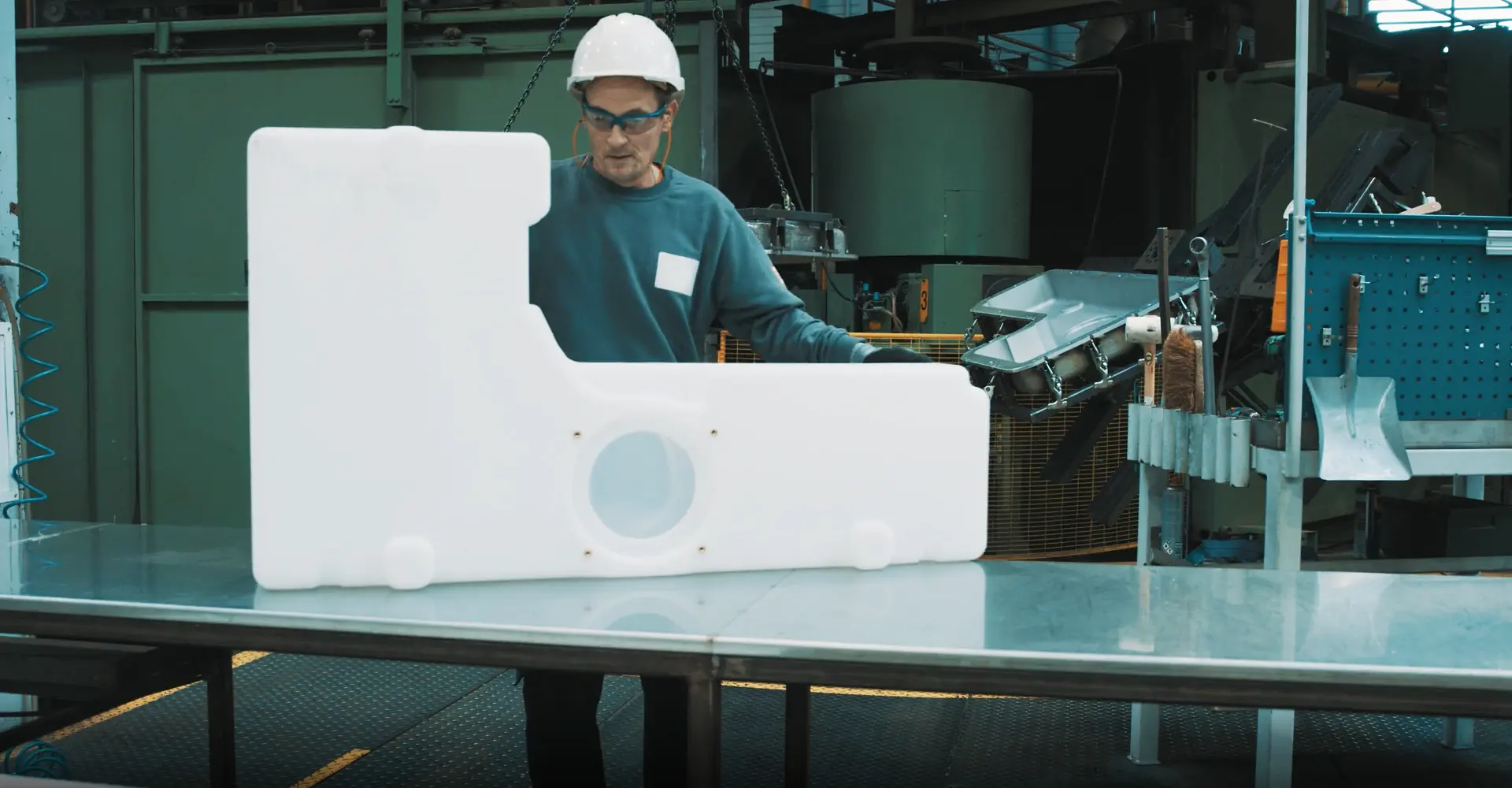

After demoulding rotomoulding, the product must be cooled to room temperature. The second cooling of the product plays a key role in ensuring its final quality and strength. The additional cooling process of the product aims to further harden and stabilise the product structure.

This step is crucial as it avoids deformation or internal stresses that could affect the appearance and functionality of the product. Depending on the specifications of the product, it may be cooled in a specialised fixture to maintain certain tolerances or parameters. The optimal cooling stages are determined for each product to ensure that the required technical properties such as strength, durability and dimensional stability are achieved. In this way, the second cooling plays an important role in the complete demoulding rototomoulding process, influencing the final quality of the product.

Check out the next step in the rotational moulding process!

Finishing & Assembling

Mariusz

Business Development Director

"Dedication sees dreams come true. Have an ambition and courage to pursue them!"

your idea

to life. Start now!