High-quality rotomoulding moulds

Rotomoulding moulds are crucial to the process of producing plastics using rotational moulding technology. They, once de-moulded, determine the external appearance of the moulded part with all its details. The inner surface of the mould is carefully contoured to ensure that the shape of the final product is accurately represented. It may contain gouges, protrusions, grooves or other details that affect the final appearance of the manufactured part. A well-made rotomoulding mould ensures a high-quality final product.

A rotomoulding mould is empty inside, as the rotational moulding process does not use pressure to mould the plastic resin. Moulds can consist of two separate upward-opening parts that connect together using hinges or clamps, or multiple parts that open in different directions for more complex designs.

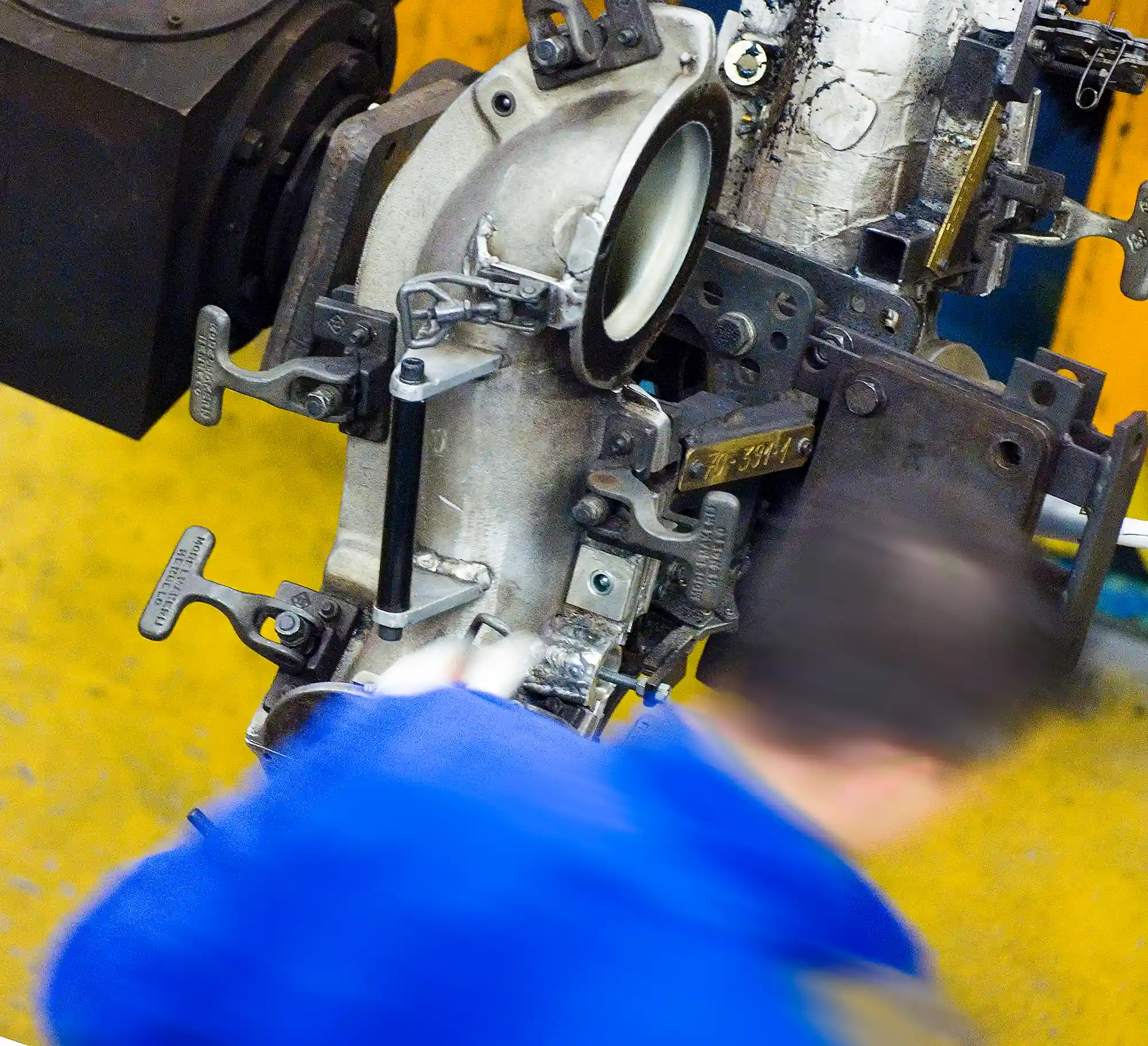

The base part of the mould is securely attached to the arm of the rotational moulding machine, while the other parts of the mould are fixed to the base part. This arrangement allows the mould to rotate evenly around the two axes and allows the mould to be removed quickly and easily once the moulding process is complete, which in turn increases the efficiency and productivity of the entire production process.

The moulds are made of high-quality materials such as steel or aluminium, which ensures exceptional durability, long life, and resistance to mechanical damage. Rotomoulding moulds are also highly thermally resistant, as they are heated in ovens to very high temperatures. The choice of material for a rotomoulding mould depends on the type of component to be produced, the life expectancy of the mould, the production budget, and the requirements for quality and repeatability of production.

Aluminium moulds for rotational moulding

Aluminium moulds are commonly used in rotational moulding due to their high design freedom combined with excellent thermal conductivity. They can perfectly withstand the high temperatures in the rotational moulding process. Aluminium rotomoulding moulds are also relatively easy to produce, making them widely used in rotomoulding.

A major advantage is their low weight compared to traditional moulds made from other materials. Aluminium moulds are lightweight, which makes them easier to handle and move during the production process, especially with larger moulds.

Aluminium moulds are made in two ways: by aluminium casting or aluminium machining. In the casting method, molten aluminium is poured into a mould to obtain the desired shape. In the machining method, a block of aluminium is cut and shaped on a CNC machine using various tools and machines to create the desired form.

Cast aluminium moulds

Cast aluminium moulds for rotational moulding are produced by pouring molten aluminium into a mould to form the desired shell. The typical wall thickness of such a mould shell is 8 mm.

Aluminium rotomoulding moulds made by casting can take complex and multi-faceted shapes, covering areas that might otherwise be difficult to remove or even impossible to undercut. This is made possible by the rotational moulding process, which allows the mould to be separated into different parts during the demoulding process, facilitating the free release of the final product with all its components.

The surface of the aluminium moulds can be finished by sandblasting or polishing to achieve the desired effect on the manufactured plastic part. Cast aluminium moulds can also replicate stone structures, wood grain or any structure that is found on the model used for aluminium casting.

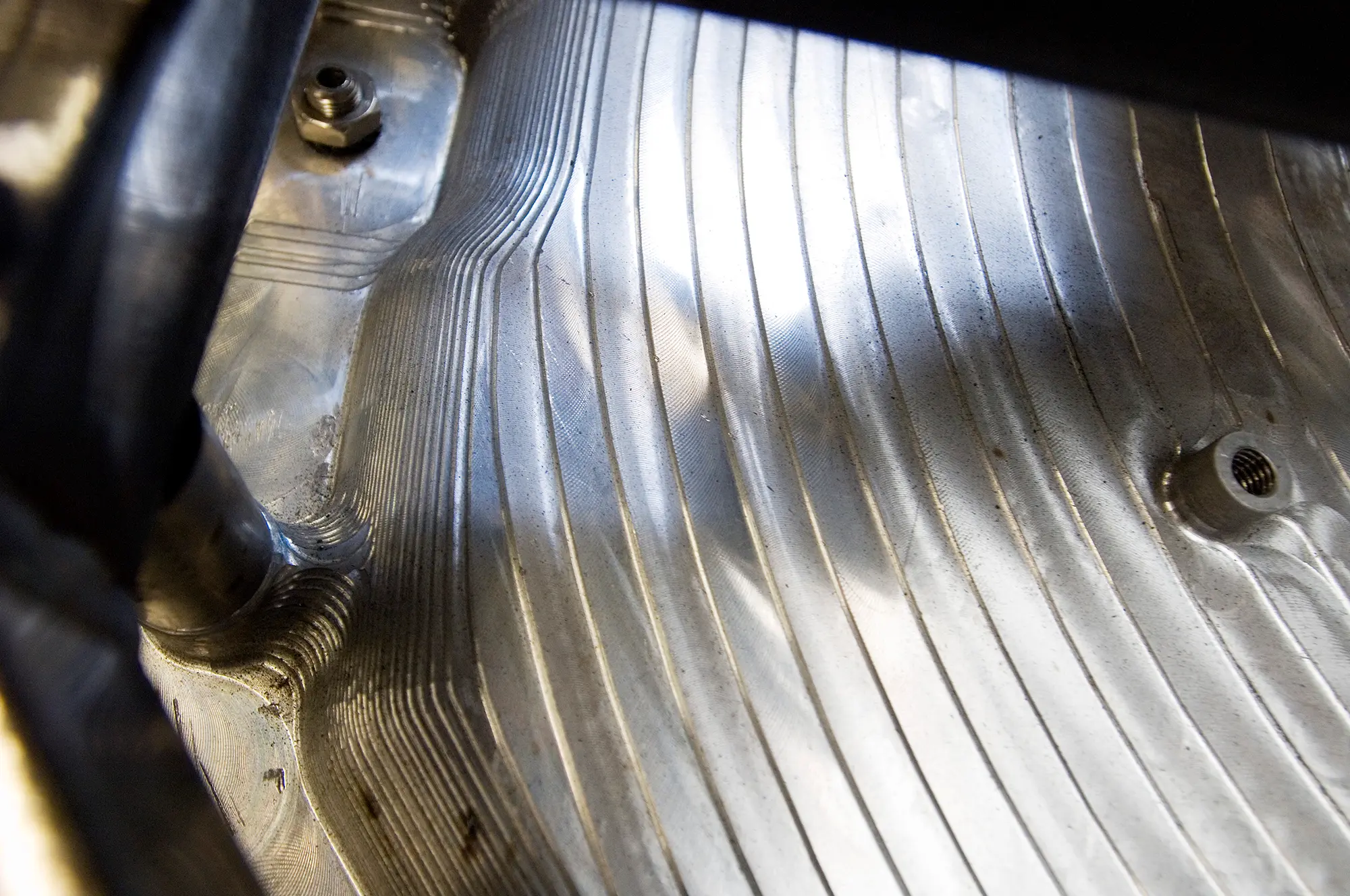

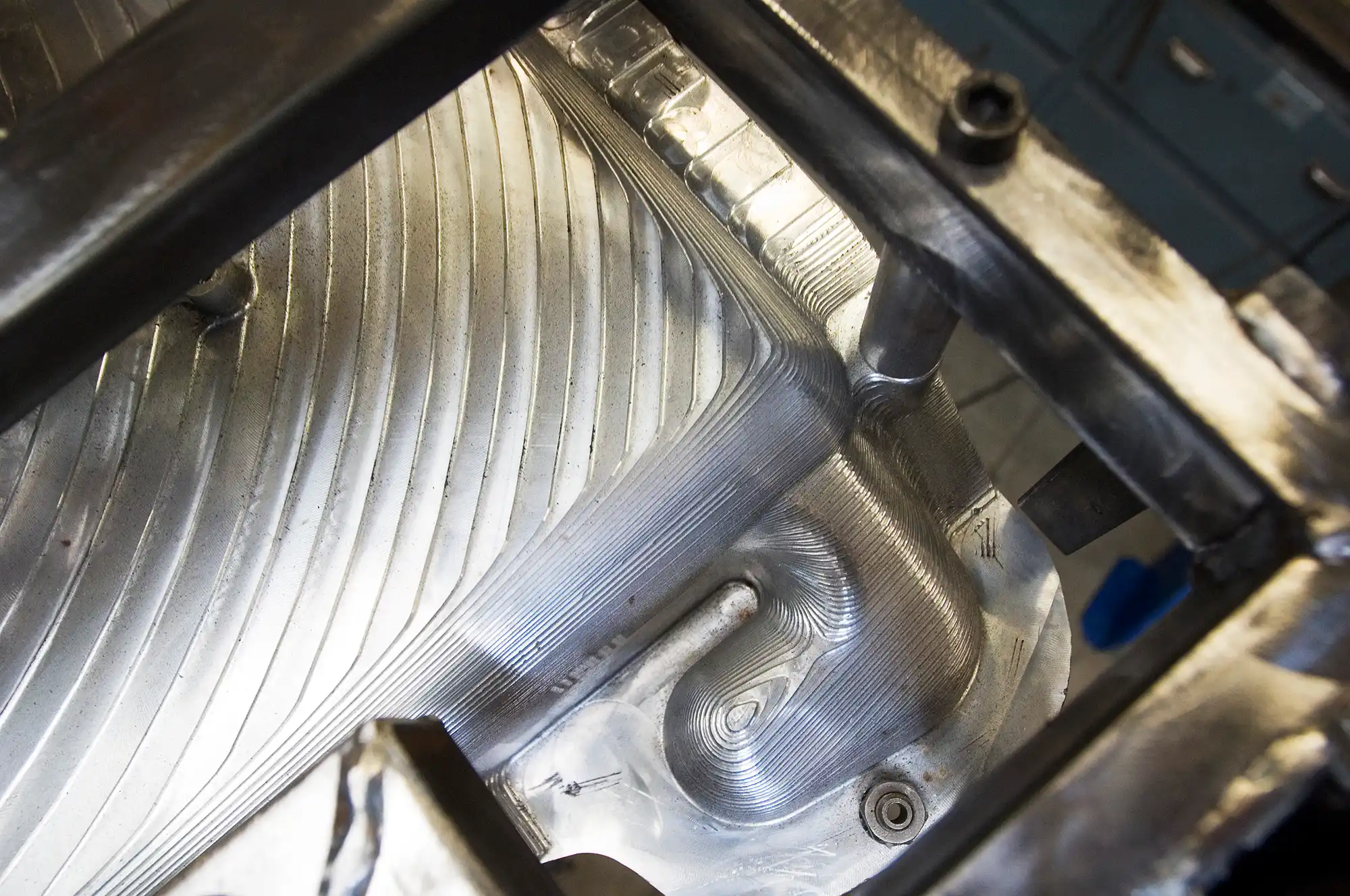

Machined aluminium moulds

Machined aluminium moulds for rotomoulding are created by milling a block of aluminium on a CNC machine, using various tools to achieve the desired shape of the mould. The production of rotomoulding moulds with machined aluminium allows a high level of detail in the finished product. The precision of moulds is very high, making moulds prepared in this way ideal for projects requiring high accuracy.

Like cast aluminium moulds, machined aluminium moulds can incorporate additional features such as threads and undercuts that might otherwise be impossible to remove during the mould disassembly process. Machined aluminium moulds enable these details to be made with precision, affecting flexibility and capability in the production of a variety of products.

The standard thickness of a machined aluminium mould is 8 mm, ensuring even heat distribution and consistent product wall thickness. Variations in thickness within the mould can affect the final wall thickness of the rotomoulded product. Changing the heat flow within the mould can lead to uneven resin distribution, resulting in areas of increased or decreased material accumulation. This in turn can lead to thicker or thinner walls in the final product, depending on the design requirements. Therefore, proper planning and execution of machined aluminium moulds is key to achieving high quality plastic products.

Steel moulds for rotational moulding

Steel moulds for rotational moulding are created by cutting and shaping sheets of steel. This stage requires precision and accuracy to ensure that the finished mould meets the design requirements. The individual steel components are then welded together to create a complete mould. Welding must be done carefully and accurately to ensure the strength and tightness of the entire mould structure. This is important to avoid resin leaks and to ensure that the mould will last over repeated use.

Moulds made of steel sheet are typically used to produce large rotoformed parts with relatively simple geometries. Like aluminium moulds, steel moulds are lightweight and easy to handle. However, the level of detail and precision that can be achieved with steel sheet moulds is not as high as with machined or cast aluminium moulds.

Preparing steel rotomoulding moulds is a complex process that requires care, precision, and the right tools. The correct execution of each step is key to achieving high quality and repeatability of the parts produced.

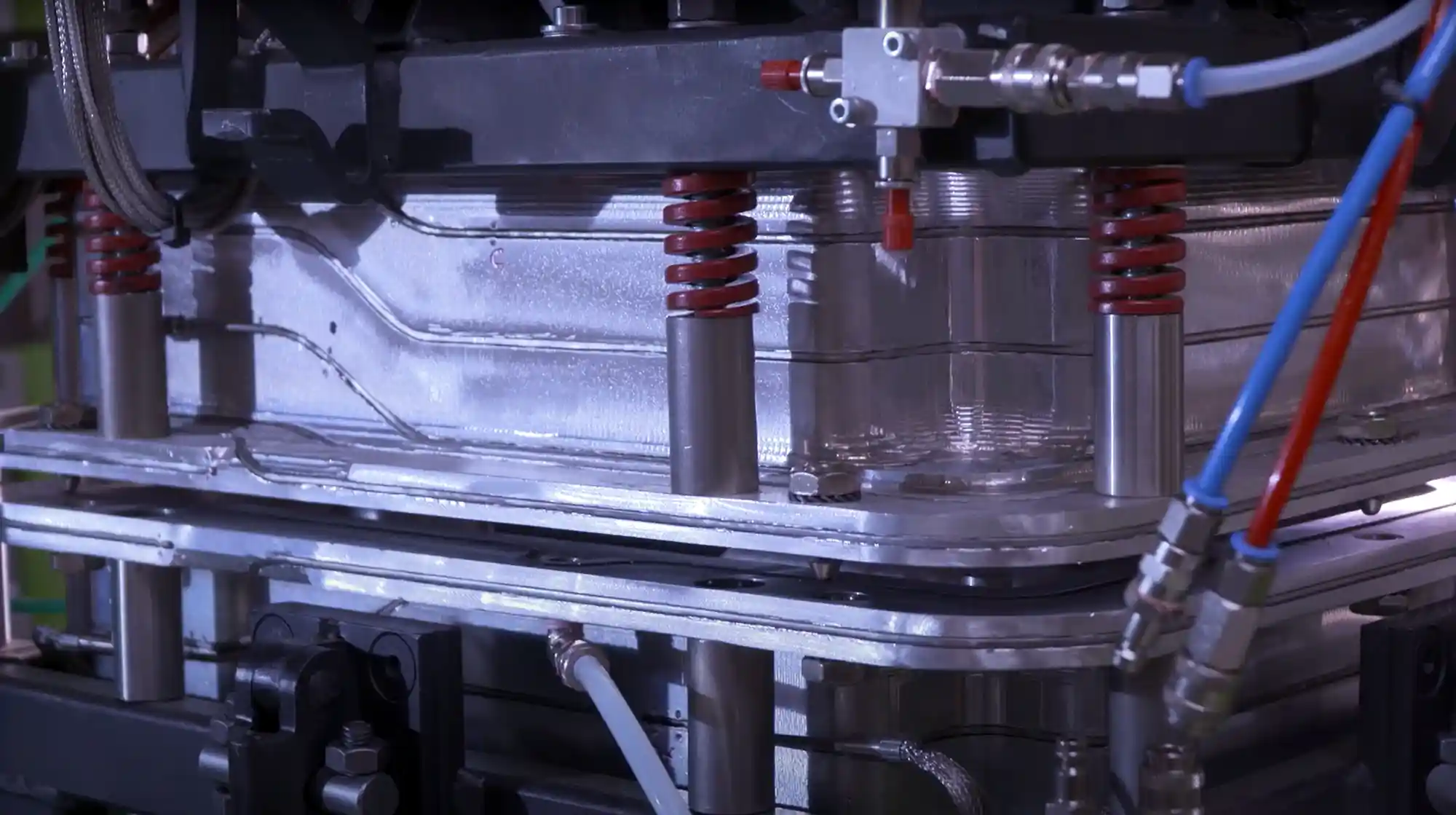

Rotomoulding moulds with integrated heating

Rotomoulding moulds with integrated heating are an innovative solution, allowing for a more efficient and controlled moulding process. These moulds have built-in electrical heating elements that are embedded in the mould shell, allowing them to be heated directly. This type of rotomoulding mould is used in machines that do not use ovens in the production process. The heating elements are arranged on the mould in a specific way. They can be placed closer together in areas where thicker walls are needed, while other areas may not be heated to create holes or cut-outs in the final product.

A heating system integrated directly into the mould eliminates the need for external heat sources, reducing mould cycle times and increasing the efficiency of the manufacturing process. Real-time temperature control allows moulding parameters to be fine-tuned to the specific requirements of each product, resulting in greater flexibility and the ability to produce a variety of parts. These types of moulds are more energy efficient, as they minimise heat loss and require less energy to achieve the desired temperatures.

Rotomoulding moulds with integrated heating can be made from cast or machined aluminium, utilising the full range of technical capabilities of aluminium moulds. This ensures high quality, precision and durability in the rotomoulding process.

Selection of rotomoulding mould - a key stage for production efficiency

Selecting the right mould for the rotational moulding process is an extremely important stage that affects the final quality and efficiency of production. The right mould choice has a key impact on the precision, strength, appearance and features of the final product.

Good tools are key to achieving high quality products, so we are happy to help you choose the right mould for your product. By analysing factors such as the quality of the finish, the size of the product and the precision required, we will suggest the best type of mould. This can be an aluminium mould, cast aluminium mould, machined aluminium or a rotomoulding mould with integrated heating, tailored to the requirements of your product. Choosing the right mould is a key step in ensuring the rotomoulding process is optimally efficient and achieves the quality standards expected.

Julia

Sales Manager

"A satisfied customer is the best business strategy of all"

your idea

to life. Start now!