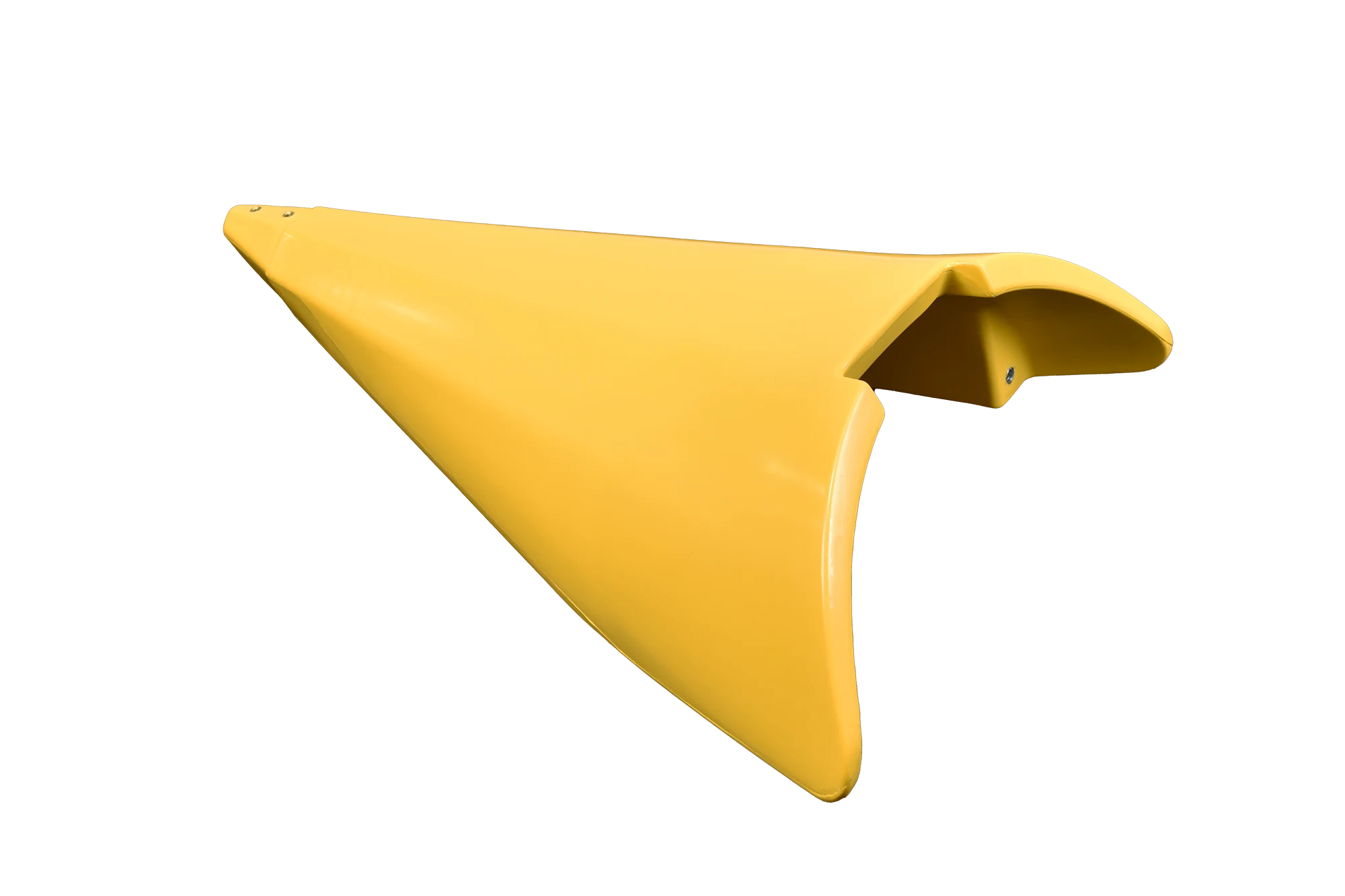

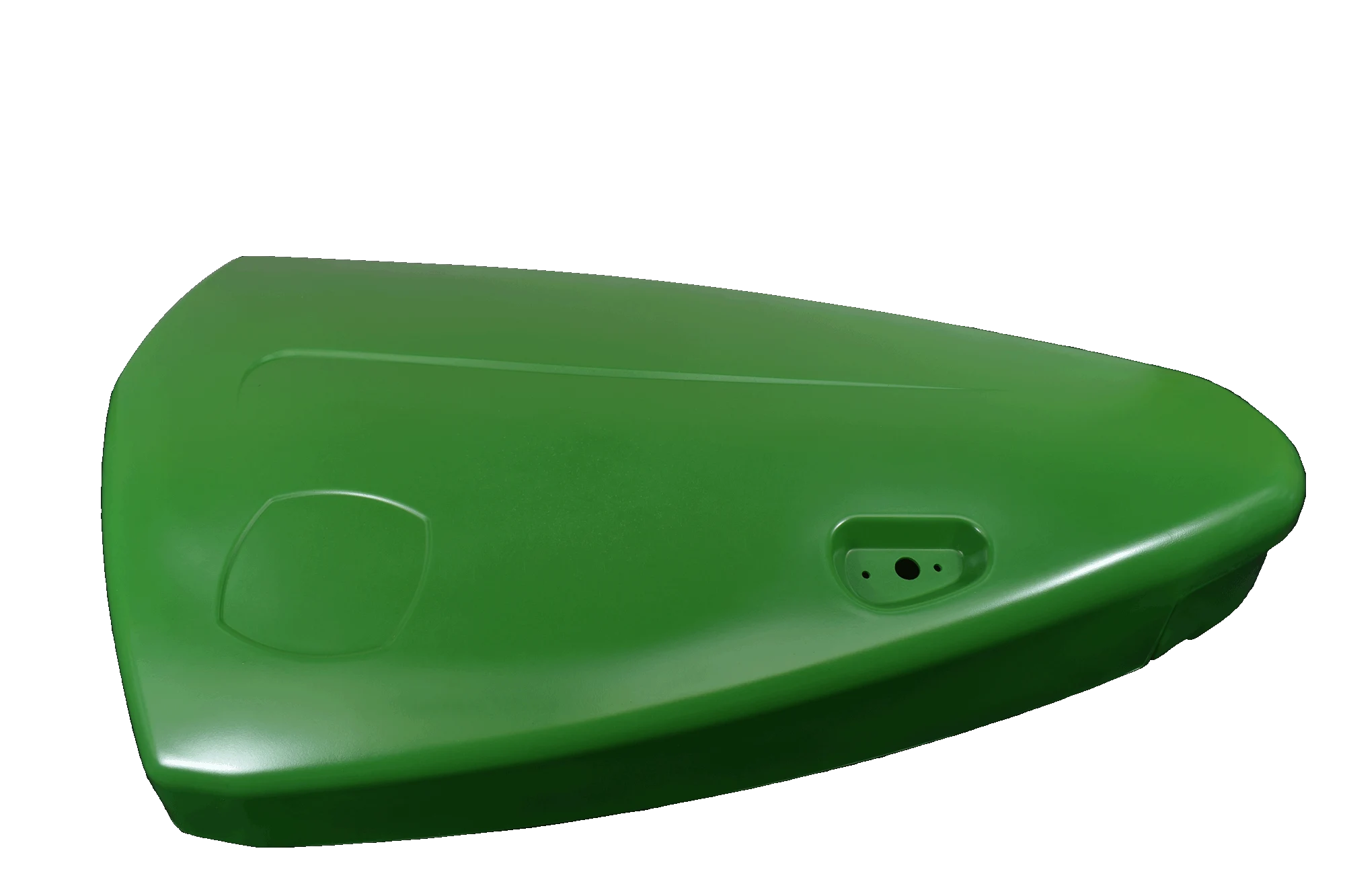

Customized designs for harvester pointers & covers

Rotomoulded harvester pointers & covers are becoming an increasingly popular choice for harvester manufacturers, due to their numerous advantages over traditional combine covers and pointers. One of the main benefits of rotomoulded harvester pointers and covers is the ability to have a customized design.

Rotomoulding is a versatile manufacturing process that allows for a wide range of shapes and sizes to be created, so harvester manufacturers can design combine hopper covers, pointers and other harvester parts that are specific to their needs and requirements. This allows for an optimal integration of the pointers and covers into the overall design of the harvester, leading to a more streamlined and efficient machine.

Unique specifications of elements for combine headers

Rotomoulded components such as harvester pointers and combine grain tank covers have some unique specifications:

- durability in an outdoor environment

- resistance to corrosion, UV radiation and varying temperatures

- design flexibility

- large variety of colours

- functional and visually appealing parts

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Adapted structure of plastic harverster covers and pointers

Customized surface structure is another advantage of rotomoulding. This allows for a specific texture or finish, which can be important for the overall design of the vehicle. For example, a harvester manufacturer might choose to create a harvester pointer and combine harvester cover with a smooth surface structure to make it easier to clean, or a cover with a rough surface structure to make the grip and handling easier. A rough finish also is more resistant against scratches or stone chips.

The customized structure of combine feeder house covers and pointers represents a significant advance in agricultural technology. By combining precision, durability and adaptability, the rotomoulded harvester header components contribute to the optimization of harvesting processes, supporting farmers in their quest for increased productivity and sustainability in modern agriculture.

Jean-Philippe

Sales Manager

"Trust is a major element: without it, no project will succeed"

your idea

to life. Start now!