Long-lasting fuel tanks for cranes

Manufacturers of cranes stand to gain several significant benefits by incorporating high-resistant rotomoulded fuel tanks into their designs. These tanks, crafted through the rotational moulding process, offer a range of advantages that enhance the performance, durability, and overall efficiency of crane systems.

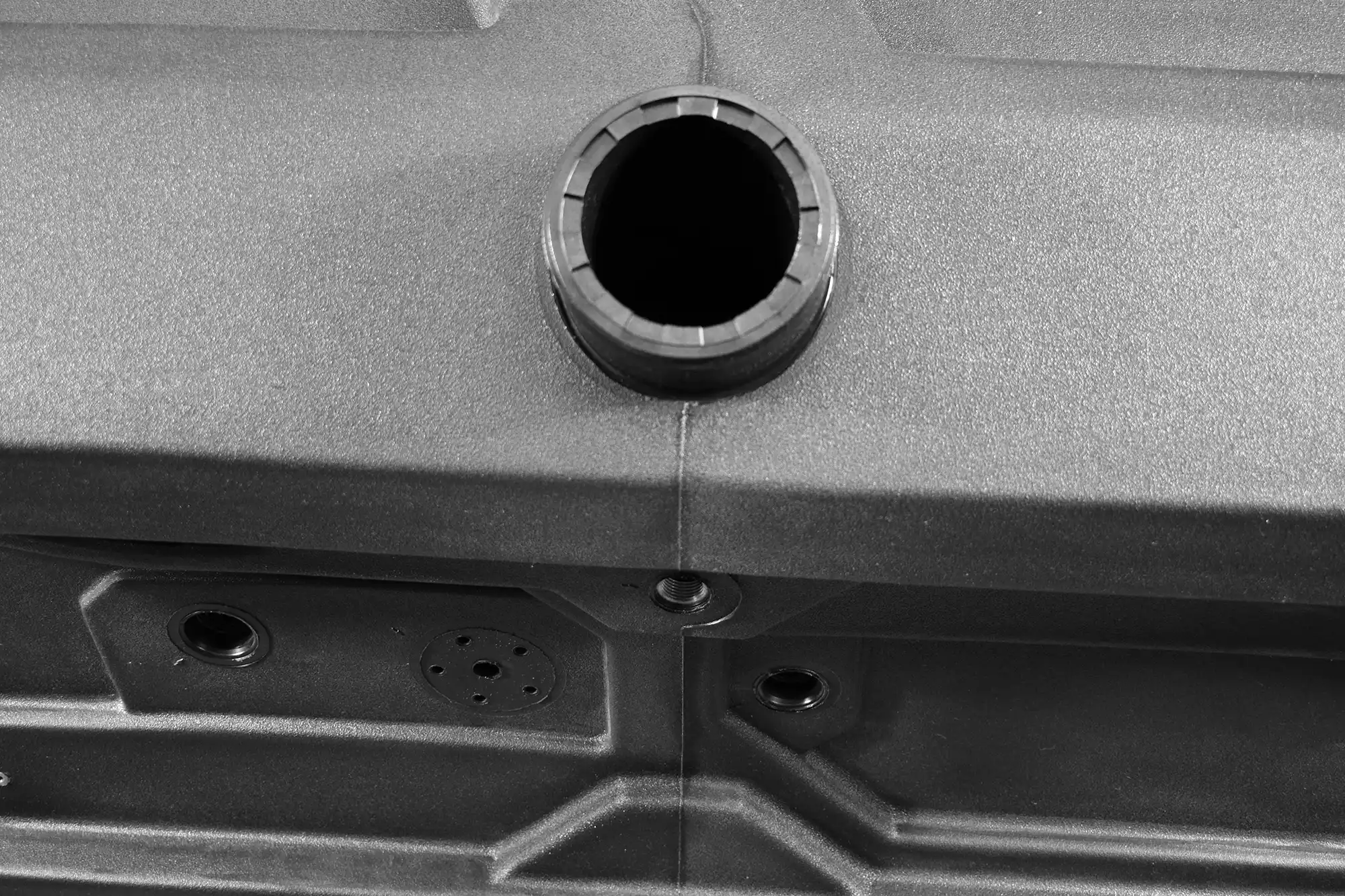

One of the key benefits lies in the exceptional durability and resilience of rotomoulded fuel tanks for cranes. These tanks, such as AdBlue tanks and hydraulic oil tanks, are constructed from high-density polyethylene (HDPE), a robust and impact-resistant material. This durability ensures that the fuel tank can withstand the harsh conditions often encountered in construction and industrial settings, such as impacts, vibrations, and exposure to various weather elements. As a result, manufacturers can expect a longer lifespan for their cranes, reducing maintenance costs and downtime.

High resistant fuel tanks for cranes

Manufacturers of construction and building machinery such as cranes benefit from the corrosion-resistant properties of rotomoulded fuel tanks. Traditional metal tanks are susceptible to corrosion, especially when exposed to moisture and various chemicals present in construction environments. The use of HDPE eliminates this concern, extending the life of the fuel tank and reducing the likelihood of system failures.

Additionally, the rotomoulding process allows for the creation of complex shapes and seamless designs. This is particularly advantageous for fuel tanks in cranes as it enables manufacturers to optimize space utilization within the crane structure. Custom shapes can be designed to fit into specific areas, maximizing fuel capacity without compromising the overall design integrity. The seamless construction also eliminates the risk of leaks, enhancing safety and environmental considerations.

Accurate 3D scanning service for rotomoulded premium products

At Rotovia, we offer a comprehensive 3D scanning service, from physical scanning to post-processing. Our scanning service accurately measures rotomoulded products in 3D, providing extremely accurate measurement data. With this service, our customers not only gain precise 3D models of their custom moulded products, but also the ability to use the collected information in the design or quality control process.

Find out more

Corrosion-free fuel tanks for cranes

The material used to make rotomoulded fuel tanks for cranes is highly resistant to the effects of Diesel and salty water. This means that they will not rust or degrade over time, making them a more reliable and long-lasting solution for crane manufacturers.

In terms of design, the tanks can be made in a variety of shapes and sizes to meet the specific needs of crane manufacturers. They can be customized to fit the shape and size of a particular crane, making them a versatile solution for a wide range of applications. Now is the time to bring your idea to life. Contact us now!

Łukasz

Sales manager

"The harder, the better."

your idea

to life. Start now!