Shape your ideas with rotomoulding design

The rotational moulding process offers unlimited design possibilities. At Rotovia, we specialise in custom design, using our knowledge and years of experience in rotomoulding design. We start a project with a consultation to understand our clients’ specific needs and goals. We then create a custom design that takes advantage of the unique features and capabilities of the rotational moulding process. This includes considering factors such as material options, product geometry and manufacturing capabilities.

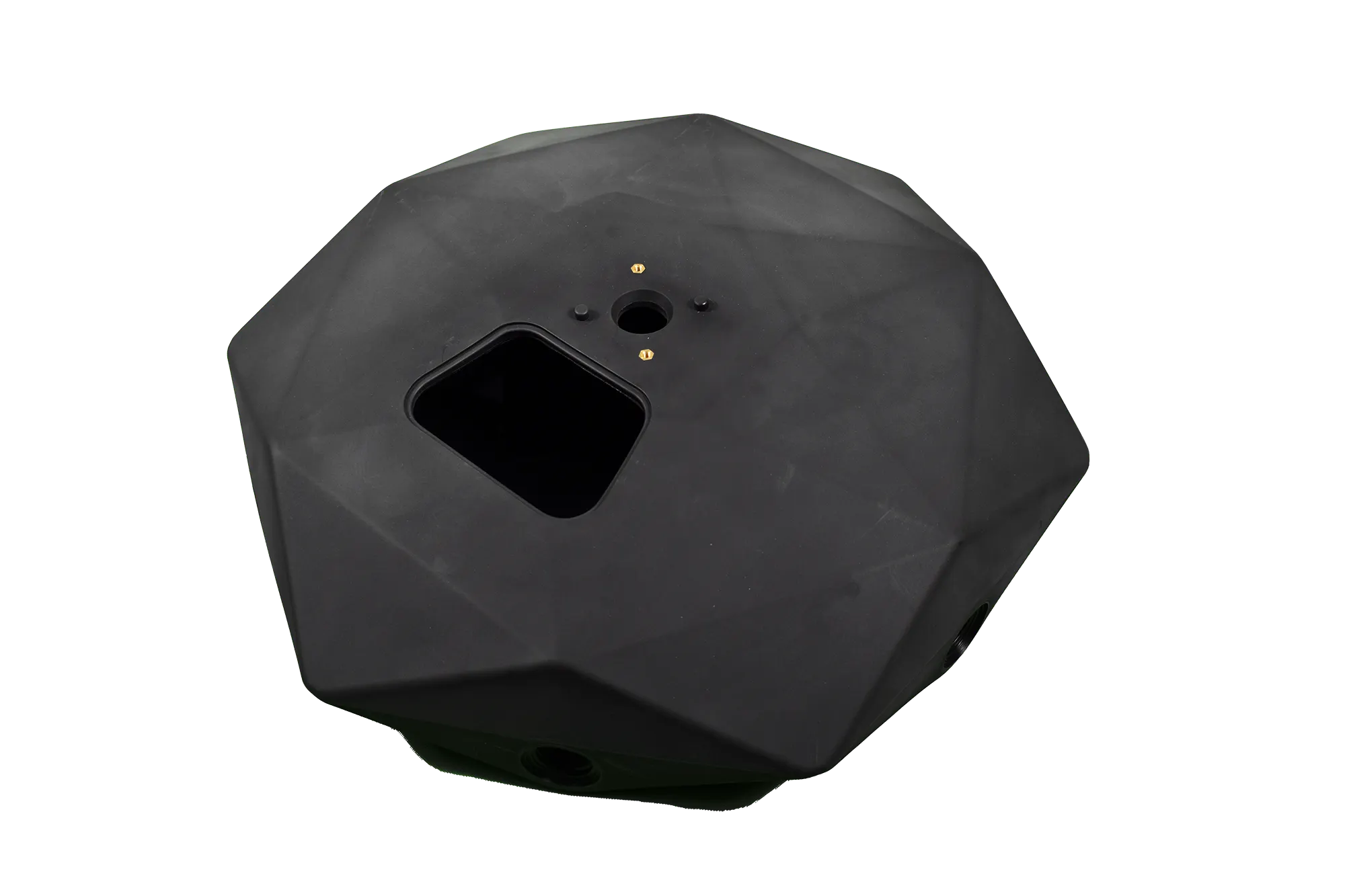

With rotomoulding, we can use a variety of surface textures, from smooth, high-gloss to matt and textured, to woodgrain, stone-effect and ribbed. Logos, lettering and pictograms can be moulded directly onto the product. Rotomoulding design opens the door to a world of customised solutions, where any idea can be realised. Whether small parts or large components, the technology ensures high quality and precision.

Throughout the entire project, we work closely with the client so that we can be sure that the custom design meets all specific requirements. At every stage of the process, we keep customers informed and involved, ensuring that the final product meets their expectations and needs.

Moulding design beyond the obvious

Rotomoulding gives unprecedented freedom when developing a new product. The process is pressure-free, allowing the build-up of mould design as a thin outer shell. The outer shell can consist of several plastic mould design departs demoulding in different directions. The rotomoulding process makes it easy to create undercuts in the same part without having to make the product from multiple parts.

It is possible to directly co-mould inner and outer threads in a product. This allows a tight connection to a hose, or a filling opening that can be closed with a screw-lid. Metal inserts can be placed in the rotomoulding design, which consequently melt completely into the product. This way, the product can be easily attached to a frame later, or parts can be mounted on the product.

The rotomoulding process results in hollow products, allowing integration of several functions into the products. For example, a double-walled funnel can be made where the hollow part can be a liquid tank or the hollow wall of rotomoulded products can be filled with foam to bring high rigidity, thermal insulation, or floating properties.

Maximizing efficiency - tools used for moulding desingn

To create the best possible design, we use several tools during the design phase of the project. 3D CAD allows us to create a digital model of the custom design, which can be easily modified and improved. With 3D printing we can produce a physical prototype of the design or specific details of it, which can be tested and evaluated for functionality and design issues.

FEA (Finite Element Analysis) can be used to predict how the new product reacts to real-world forces, temperature and vibration, allowing us to identify and address any potential weaknesses in the plastic mould design before a mould is made. With this combination of tools, we can create a mould design that is optimized for performance, cost, and manufacturability. It enables us to identify and resolve any issues early in the rotomoulding design process, resulting in a more efficient and cost-effective outcome for our customers.

Łukasz

Sales manager

"The harder, the better."

your idea

to life. Start now!