Nylon for rotomoulding - the future of durable products

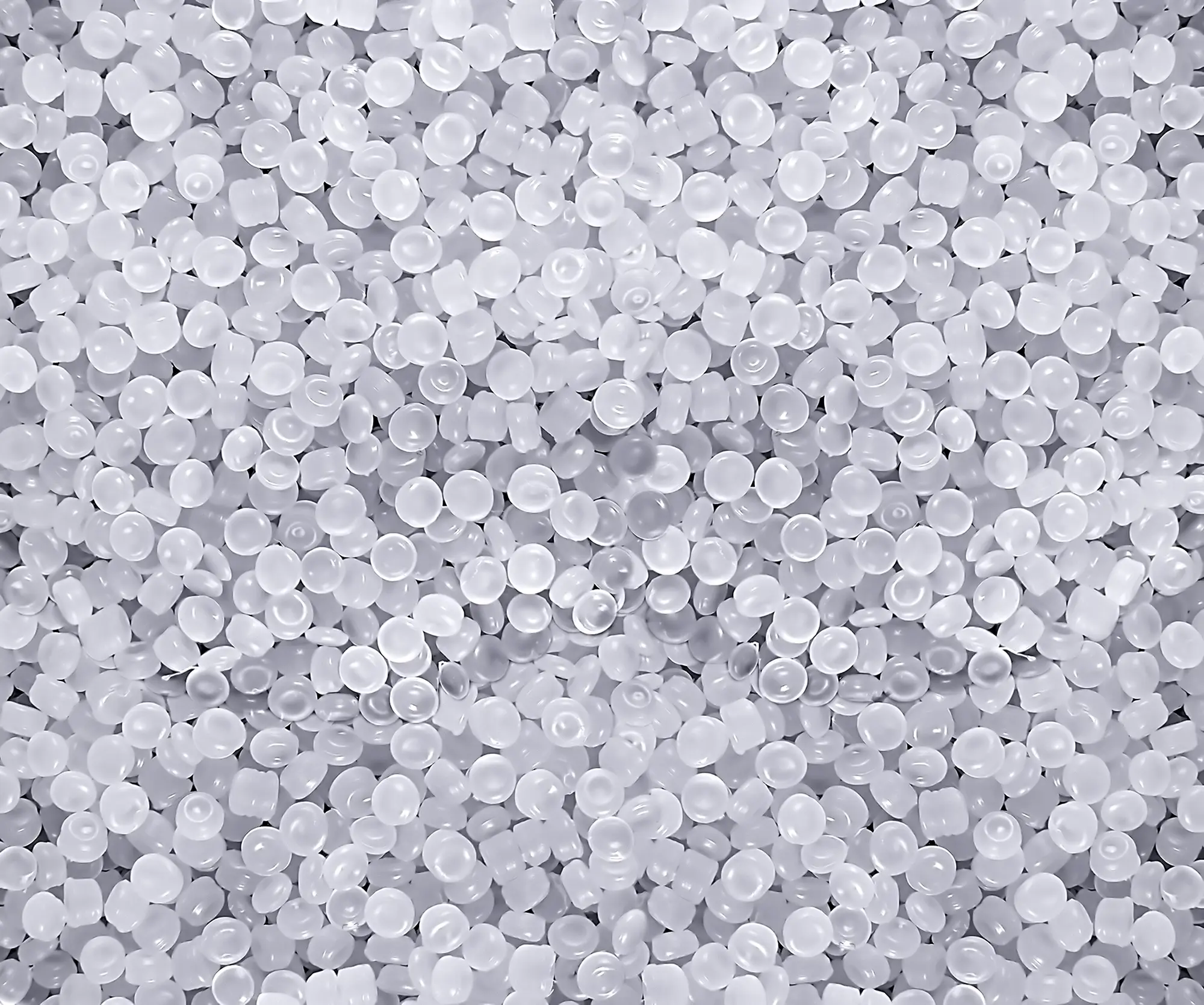

Nylon for rotomoulding is a thermoplastic polymer called polyamide, or short: PA. Moulded nylon has a unique combination of strength and heat resistance. It is one of the toughest materials and preferred for specific products like tanks for hydraulic oil.

One of the main advantages of using nylon for rotomoulding is its high strength-to-weight ratio. It opens opportunities to save on weight: PA is 6 times lighter than steel. Polyamide is much stronger than most other plastics, making it ideal for products that need to withstand heavy loads. Additionally, high performance nylon is a very tough and durable material that can withstand impact and wear and tear.

Polyamide is also highly resistant to heat, many chemicals, and UV light, which makes it suitable for outdoor applications. It can withstand temperatures up to 150 °C. This combination of properties makes it suitable for use in applications like hydraulic tanks for vehicles: high temperatures, pressurized, oil resistant and outdoor-proof.

Moulded nylon perfectly perfectly resistant to chemicals

Moulded nylon shows a very good resistance to fuels, oils and greases. Compared to polyolefins such as PE and PP, polyamide has outstanding barrier properties against hydrocarbons: the permeability is very low.

PA6 nylon, PA11 nylon, and PA12 nylon are all types of polyamide (PA) or nylon. Processing PA6 nylon requires an inert atmosphere, typically nitrogen, to prevent degradation. Although PA11 nylon and PA12 nylon do not require the inert atmosphere, processing of polyamide requires precise manufacturing conditions.

The hygroscopicity of PA6 nylon is a factor to consider – this adds complexity during processing. The water absorption of both PA11 nylon and PA12 nylon is low, below 1% at room temperature (50% RH), which is about five times less than of PA6 nylon. Especially PA6 nylon can be brittle right after moulding. It needs to absorb moisture after moulding to get its flexibility. The difference in moisture pick-up between PA6 versus PA11 nylon and PA12 nylon also has an impact on dimensional stability: the low hygroscopicity of PA and PA12 nylon results in high dimensional stability of the products.

High performance nylon - ideal for demanding products

Using nylon for rotomoulding (PA), a high yield of structural polymers is achieved in the rotational moulding process. It is a versatile material that can be used in a wide range of rotomoulding applications: its unique combination of stiffness, high temperature stability and chemical resistance makes it an ideal choice for many products.

Rotomoulding technology enables the precise shaping and moulding of high-performance nylon, accommodating a diverse array of intricate forms and complex designs. This adaptability positions molded nylon as an optimal choice for products necessitating meticulous details and specific configurations. Different types of moulded nylon offer varying properties suitable for specific applications applications such as higher abrasion resistance, better resistance to high temperatures or specific elasticity, which allows them to be widely used in industry.

your idea

to life. Start now!